Dosing pumps play a critical role in various industries by ensuring the precise and controlled delivery of fluids or chemicals. When selecting a high-quality dosing pump, several key features and specifications should be carefully considered.

Let’s delve into the essential elements that contribute to a superior dosing pump.

-

Accuracy and Precision

The primary function of a dosing pump is to deliver precise amounts of fluid consistently. Therefore, accuracy and precision are paramount. Look for pumps that offer a high degree of accuracy, typically expressed as a percentage of the set flow rate. Additionally, repeatability, or the pump’s ability to deliver the same volume consistently over multiple cycles, is crucial for process control and product quality.

-

Flow Rate and Pressure Capabilities

The flow rate and pressure capabilities of a dosing pump should align with your specific application requirements. Carefully assess the required flow rate range and maximum pressure for your process, ensuring the pump can handle these demands without compromising performance or accuracy.

-

Chemical Compatibility

The materials used in the pump’s construction must be compatible with the chemicals or fluids being dosed. Consider factors like corrosiveness, abrasiveness, and temperature to select a pump with suitable wetted parts, such as stainless steel, PTFE, or other specialized materials.

-

Durability and Longevity

Dosing pumps often operate in demanding environments, subject to continuous use and exposure to various chemicals. Choose a pump built with robust materials and designed for long-term durability. Look for features like a sturdy housing, high-quality seals, and reliable drive mechanisms to ensure a long service life and minimize downtime.

-

Control and Automation

The level of control and automation offered by a dosing pump can significantly impact its ease of use and integration into your process. Consider features like adjustable flow rates, programmable dosing schedules, remote monitoring capabilities, and compatibility with automation systems to streamline operations and enhance process control.

-

Maintenance and Serviceability

Ease of maintenance and serviceability are vital considerations. Choose a pump with readily accessible components, simple maintenance procedures, and readily available spare parts. Self-priming capabilities and the ability to handle air or gas entrainment can also simplify operation and reduce maintenance requirements.

-

Safety Features

Safety is paramount in any industrial setting. Look for dosing pumps equipped with safety features like leak detection, pressure relief valves, and alarms to protect personnel and equipment.

-

Energy Efficiency

Energy-efficient dosing pumps can contribute to significant cost savings over time. Look for pumps with high efficiency ratings and features like variable speed drives to optimize energy consumption based on demand.

-

Manufacturer Reputation and Support

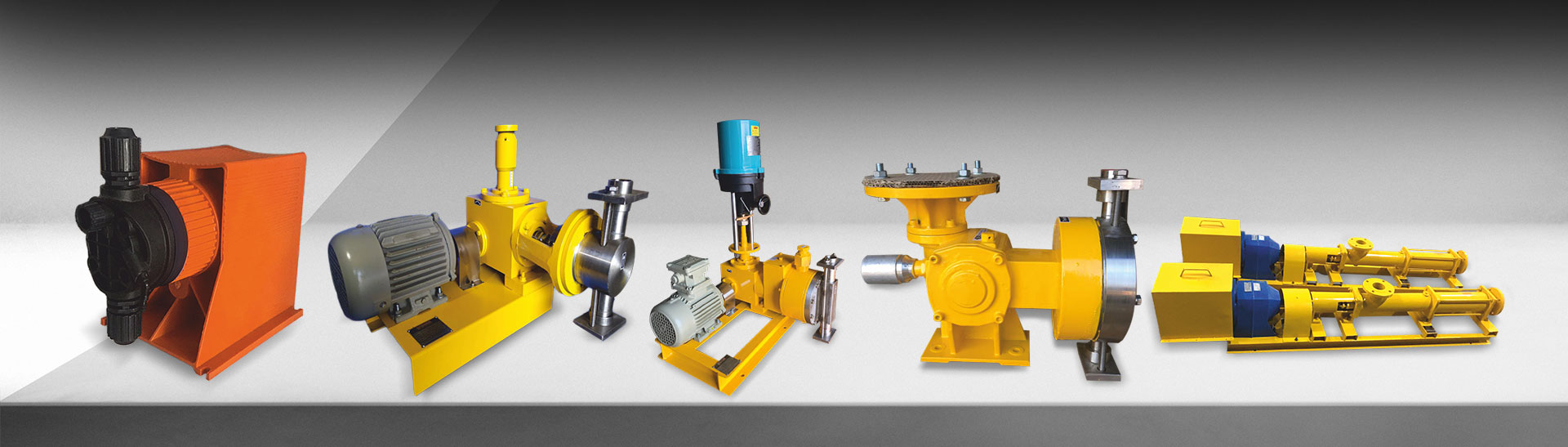

Selecting a dosing pump from a reputable manufacturer like Verito Engineering Pvt Ltd with a proven track record is essential. Consider factors like the company’s experience, technical expertise, customer support, and warranty offerings.

-

Cost

While cost is an important factor, it should be considered in conjunction with the other features and specifications. A high-quality dosing pump may have a higher upfront cost but can provide long-term value through improved performance, reliability, and reduced maintenance expenses.

Choosing the right dosing pump requires careful consideration of several key features and specifications. By prioritizing accuracy and precision, flow rate and pressure capabilities, chemical compatibility, durability, control and automation, maintenance and serviceability, safety features, energy efficiency, manufacturer reputation, and cost, you can select a high-quality dosing pump that will meet your specific needs and deliver reliable performance for years to come.

Remember: Investing in a top-notch dosing pump can enhance process efficiency, improve product quality, and reduce operational costs. Make an informed decision by thoroughly evaluating your requirements and selecting a pump that aligns with your industry and application demands.