A dosing pump, often referred to as a metering pump, is designed to deliver a precise amount of fluid or chemical into a process stream. These pumps are widely used across various industries, including water treatment, chemical manufacturing, and food processing, where accuracy in fluid handling is crucial. Below is a detailed overview of how dosing pumps operate and the components that contribute to their functionality.

How does a Dosing Pump Work?

Operating Principle

Dosing pumps are a type of positive displacement pump, meaning they move fluid by trapping a fixed volume of it and forcing that volume into the discharge pipe. The basic principle involves an oscillating motion, usually driven by a motor or actuator, which allows the pump to move fluid in a controlled manner.

At its core, the pump works by drawing liquid from a reservoir into its chamber. As the motor activates, it creates a vacuum that sucks the fluid into the pump’s inlet. Once inside, the fluid is pushed out via the outlet, and this entire cycle is repeated continuously.

Flow Rate Control

One of the key aspects of a dosing pump is its ability to control the flow rate accurately. This is typically managed by adjusting the speed of the motor and the stroke length of the pump. Additionally, check valves are used to prevent backflow, ensuring that the fluid only moves in one direction. This precision is essential for applications like water treatment, where the exact dosage of chemicals is vital for safety and efficiency.

Key Components of a Dosing Pump System

To better understand how a dosing pump works, it’s important to know the major components involved:

- Chemical Tank or Container: This is where the product being dosed is stored. It holds the chemical or fluid that needs to be injected into the system.

- Foot Valve: A one-way valve attached to a suction line, this component ensures that the pump remains primed. It is placed at the bottom of the chemical tank and is weighted to stay submerged in the fluid. Some models have a float switch to activate an alarm when the product level runs low.

- The Pump: The pump is usually made from chemical-resistant materials like PVC, PE, or stainless steel, depending on the fluid being handled. It has two major connections: a suction line for drawing in fluid and a dosing line for delivering it. The pump’s mechanics can vary, but the most common type is a diaphragm pump.

- Dosing Line: Typically made from rigid PVC or PE tubing, the dosing line transfers the fluid from the pump to the process pipe or vessel. In certain applications involving high pressure or temperature, this line may be made from stainless steel.

- Injector: The injector is a one-way valve where the chemical is injected into the flow stream. It helps ensure that the chemical enters the fluid at the right point, often in the center of the stream to promote better mixing. The one-way valve also prevents backflow, which could otherwise damage the pump.

- Control System: A dosing pump may be integrated with a control system to regulate its operation. This can range from simple timers to sophisticated control systems like SCADA (Supervisory Control and Data Acquisition) systems, which monitor variables like pH levels, chlorine concentration, and more to ensure accurate dosing.

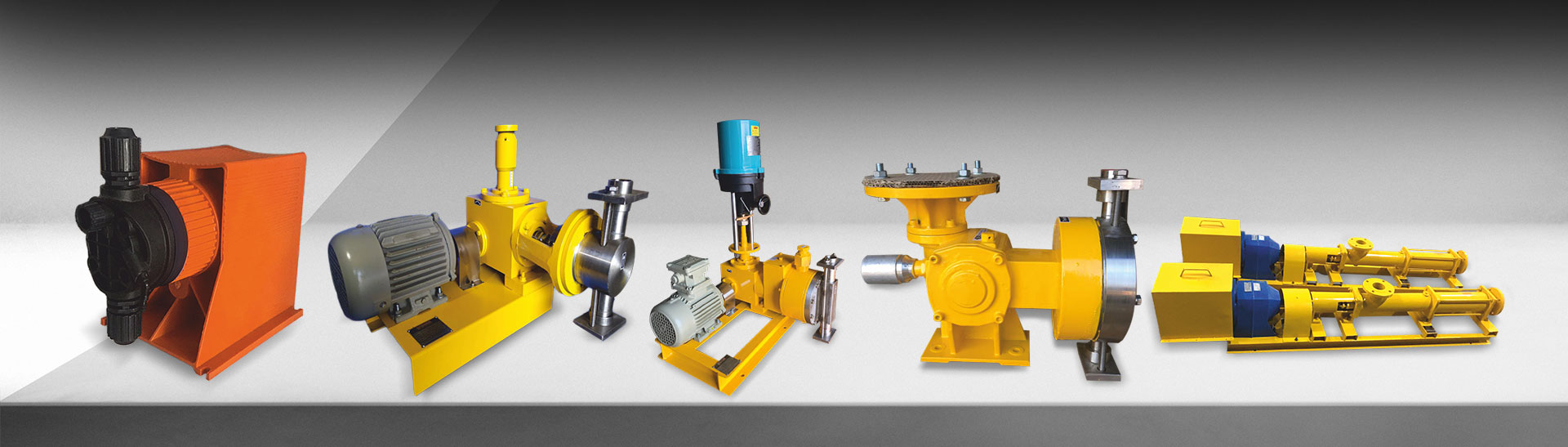

Types of Dosing Pumps

While there are several types of dosing pumps, the diaphragm pump is the most commonly used, especially in industries that require high reliability and minimal maintenance. Diaphragm pumps operate by using a flexible diaphragm to move fluid into and out of a displacement chamber. The diaphragm’s movement creates suction, pulling the fluid into the chamber and then pushing it out during the pump’s discharge cycle.

Diaphragm pumps are popular because they have no internal parts that rub against each other, minimizing wear and tear. Furthermore, they don’t require seals or lubrication in the pump head, which prevents the possibility of leaks or contamination.

Interested in learning more about the different types of dosing pumps? Check out our comprehensive guide on the types of dosing pumps for detailed insights!

Other Methods of Dosing Pump Operation

Depending on the brand and model, dosing pumps may use other mechanisms, such as piston or plunger pumps. These operate similarly to diaphragm pumps but use a piston to displace the fluid. These designs are often employed in applications where higher pressures are needed. However, piston pumps generally require more maintenance due to the friction between the moving parts.

Precision and Accuracy in Dosing

Accuracy is a key factor in the performance of dosing pumps. In most dosing applications, the precise measurement of fluids is critical. To ensure the correct amount of fluid is delivered, dosing pumps are equipped with control systems that can be fine-tuned. This helps maintain accuracy, especially in complex systems where multiple variables need to be monitored and adjusted.

For example, advanced control systems can adjust dosing rates based on real-time data from sensors measuring variables such as flow rate, pH levels, or chemical concentrations in the system. This adaptability makes dosing pumps highly efficient and effective for continuous processes.

Final Words

Dosing pumps play a critical role in numerous industrial applications, ensuring that the correct volume of fluid is delivered with precision. Their design, which incorporates key components like the foot valve, injector, and control system, allows them to function effectively in various environments. With advances in technology, these pumps continue to offer reliable, accurate, and efficient operation in fields requiring meticulous fluid handling.

Whether it’s a diaphragm pump for chemical dosing in water treatment or a piston pump for high-pressure applications, dosing pumps remain an indispensable part of modern industry.

For top-quality dosing pumps, Verito Engineering Pvt. Ltd. stands out as one of the best manufacturers. Their range of products is designed to meet the highest standards of precision and reliability, making them a trusted name in the industry.