Achieving consistent dosing of fluids with varying viscosities is a challenge across multiple industries, from chemical processing to food manufacturing. Viscosity refers to a fluid’s resistance to flow, and it can affect the precision of dosing, especially when the fluid’s viscosity changes under different conditions like temperature or pressure. For dosing pumps to function optimally with fluids of different viscosities, specialized management techniques and pump configurations are necessary.

In this article, we will explore the factors influencing fluid viscosity, the challenges it presents in dosing, and the best practices to ensure consistent dosing performance with variable viscosity fluids.

Understanding Viscosity and Its Impact on Dosing

Viscosity, often described as the “thickness” of a fluid, affects how easily a fluid flows. For instance, water has a low viscosity, while substances like molasses or grease have higher viscosities. When dosing pumps are used to handle fluids with varying viscosities, the changes in flow properties can lead to inconsistent dosing unless properly managed.

3 Key factors that affect fluid viscosity include:

- Temperature: Many fluids become less viscous (thinner) at higher temperatures and more viscous (thicker) at lower temperatures.

- Pressure: In certain cases, pressure changes can alter the viscosity of fluids, making it harder to achieve consistent dosing.

- Shear Sensitivity: Some fluids, like non-Newtonian fluids, change their viscosity based on the shear force applied to them, complicating dosing operations.

These variations mean that systems designed for low-viscosity fluids may not perform well with thicker fluids unless they are properly calibrated or designed to accommodate these changes.

4 Challenges of Dosing Variable Viscosity Fluids

Dosing pumps rely on precise flow rates to ensure the correct amount of fluid is delivered. However, when handling fluids with different viscosities, several challenges arise:

-

Flow Rate Instability

As viscosity increases, it becomes more difficult for a pump to maintain a consistent flow rate. Without adjustments, this could lead to overdosing or underdosing, particularly when dealing with thick fluids like gels or syrups.

-

Increased Backpressure

High-viscosity fluids can generate significant backpressure in the dosing system, especially in long pipelines or small-diameter tubing. This backpressure can cause the pump to work harder, potentially reducing its efficiency and lifespan.

-

Pumping Efficiency

Dosing pumps, such as diaphragm or peristaltic pumps, may struggle to maintain performance when dealing with fluids that have drastically different viscosities. For example, the fluid may not fill the pump chamber as quickly, leading to inconsistent dosing volumes.

-

Cavitation and Airlocks

When dealing with highly viscous fluids, there’s an increased risk of air pockets or cavitation forming in the dosing system. This can disrupt the fluid flow and cause dosing inaccuracies, especially in systems that aren’t equipped to handle such conditions.

6 Best Practices for Achieving Consistent Dosing with Variable Viscosity Fluids

To effectively manage and achieve consistent dosing with fluids of varying viscosities, it’s important to consider several strategies and best practices.

-

Use of Adaptive Dosing Pumps

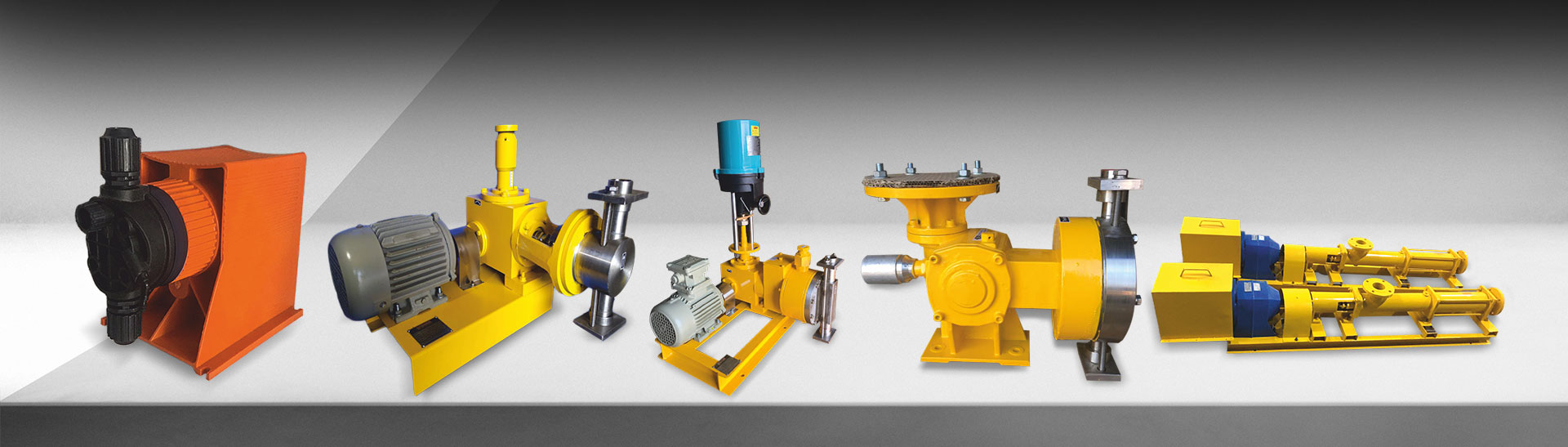

Selecting the right type of dosing pump is crucial. For handling fluids with different viscosities, pumps such as diaphragm pumps, progressive cavity pumps, or peristaltic pumps are well-suited. These pumps can manage high-viscosity fluids more effectively due to their design, which minimizes shear and pressure losses.

- Peristaltic Pumps: These pumps are highly effective for viscous fluids since the fluid is contained in a flexible tube, eliminating the risk of contamination or pressure loss.

- Diaphragm Pumps: These pumps can handle both high- and low-viscosity fluids, making them versatile for varying fluid types.

-

Temperature Control

Controlling the temperature of the fluid can help stabilize viscosity. For example, heating high-viscosity fluids will reduce their thickness and make them easier to pump. In contrast, cooling low-viscosity fluids can help achieve more consistent dosing when needed.

-

Flow Rate Monitoring and Adjustment

Integrating flow meters and feedback systems can help maintain consistent dosing by allowing real-time adjustments to the pump’s performance. For instance, if the viscosity increases due to a drop in temperature, the system can automatically adjust the pump speed or pressure to compensate for the change.

-

Using Variable-Speed Pumps

Variable-speed dosing pumps are designed to adapt to fluctuations in viscosity by adjusting the speed and pressure of the pump to maintain a consistent flow rate. This adaptability ensures that dosing remains accurate, even as the fluid’s viscosity changes.

-

Calibration and Regular Maintenance

Regular calibration of the dosing pump is essential for maintaining accuracy, especially when working with fluids of different viscosities. Maintenance activities such as checking for wear in the pump components, cleaning tubing, and ensuring that valves are functioning properly will help prevent dosing inconsistencies caused by mechanical issues.

-

Positive Displacement Pumps for High-Viscosity Fluids

Positive displacement pumps are particularly suitable for handling fluids with variable viscosities. They work by trapping fixed amounts of fluid and forcing it through the system, regardless of its viscosity. This type of pump is ideal when dealing with highly viscous substances like resins, oils, or gels.

Managing the dosing of fluids with varying viscosities presents unique challenges, but with the right equipment and techniques, consistent dosing can be achieved. By selecting the appropriate pump, controlling temperature, using variable-speed pumps, and implementing real-time monitoring systems, you can maintain accuracy and efficiency in dosing operations across different industries.

Understanding fluid behavior and its impact on dosing systems is crucial for industries ranging from pharmaceuticals to wastewater treatment. Adopting adaptive technologies and best practices can ensure optimal performance, reducing the risks of underdosing or overdosing, and improving overall system efficiency.

Whether you’re dealing with thick oils or thin chemical solutions, Verito Engineering Pvt Ltd offers a range of dosing pumps that ensure precise and reliable performance, regardless of the fluid viscosity. Invest in the right dosing technology and manage variable viscosity fluids with confidence.