In today’s fast-paced industrial landscape, automation has become a game-changer for various processes, including dosing systems. With the integration of Internet of Things (IoT) technologies, businesses can achieve unparalleled control and precision in their dosing operations. This article explores how to automate dosing systems effectively and the role of IoT in optimizing dosing precision.

What are Dosing Systems?

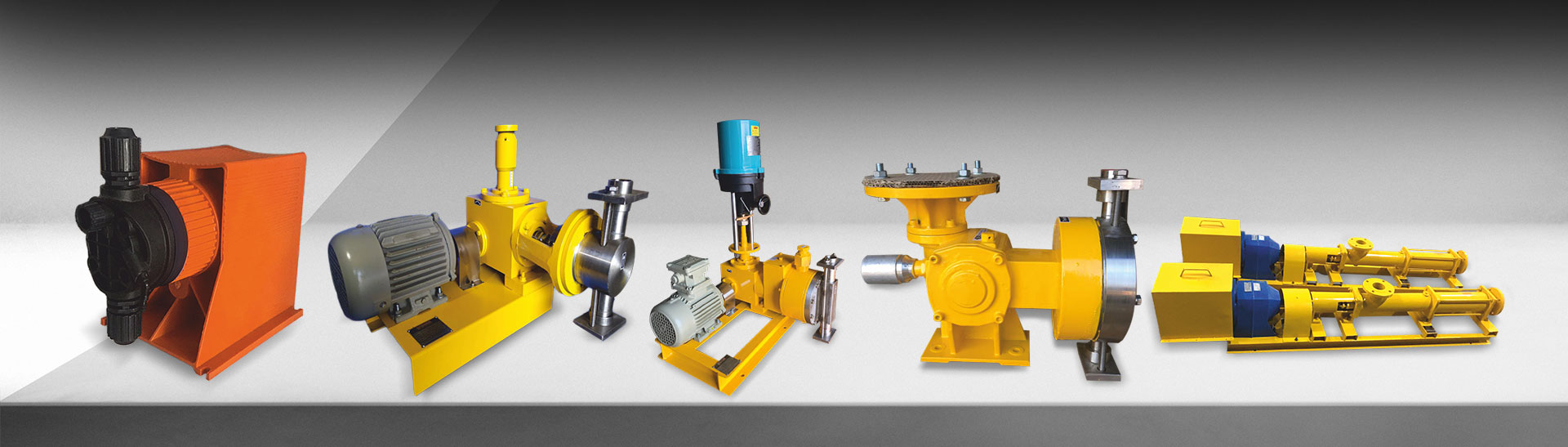

Dosing systems are used to inject precise amounts of liquids or chemicals into a process. These systems are critical in industries such as water treatment, pharmaceuticals, food and beverage, and chemical processing, where accuracy and consistency are essential.

Read more here.

Importance of Precision in Dosing

Accurate dosing ensures the right chemical concentrations, which helps maintain product quality, reduces waste, and minimizes environmental impact. In industries where compliance with safety regulations is mandatory, precise dosing is not just beneficial; it’s essential.

The Role of Automation in Dosing Systems

Benefits of Automation

- Increased Accuracy: Automated dosing systems can deliver precise amounts of chemicals, reducing human error.

- Improved Efficiency: Automation speeds up the dosing process, allowing for higher production rates.

- Real-Time Monitoring: Automated systems can continuously monitor dosing levels, providing instant feedback and adjustments.

- Reduced Labor Costs: With automation, fewer personnel are needed to operate dosing systems, cutting labor expenses.

Key Components of Automated Dosing Systems

- Sensors: Monitor parameters such as flow rate, pressure, and chemical concentration.

- Controllers: Central units that process data from sensors and adjust dosing rates accordingly.

- Actuators: Mechanical devices that carry out dosing actions based on commands from the controller.

- User Interface: Dashboards that allow operators to monitor and adjust system settings easily.

What is IoT?

The Internet of Things (IoT) refers to a network of interconnected devices that can communicate and exchange data over the internet. In dosing systems, IoT enables real-time data collection and analysis, leading to smarter decision-making.

How IoT Enhances Dosing Precision

- Remote Monitoring and Control: IoT allows operators to monitor dosing systems from anywhere, enabling quick adjustments and minimizing downtime.

- Data Analytics: Collected data can be analyzed to identify trends, predict maintenance needs, and optimize dosing processes.

- Integration with Other Systems: IoT can integrate dosing systems with other industrial processes, creating a seamless workflow that enhances overall efficiency.

- Alerts and Notifications: Automated alerts can inform operators of any discrepancies in dosing, allowing for immediate corrective actions.

6 Steps to Automate Dosing Systems

-

Assess Your Current System

Evaluate your existing dosing system to identify areas that require improvement. Consider factors such as:

- Accuracy of current dosing methods

- Frequency of human errors

- Time taken for manual adjustments

-

Choose the Right Automation Technology

Select automation solutions that align with your specific needs. Options include:

- PLC (Programmable Logic Controller): Ideal for complex operations with multiple inputs and outputs.

- SCADA (Supervisory Control and Data Acquisition): Best for large-scale operations requiring centralized monitoring.

-

Integrate Sensors and Controllers

Implement sensors to monitor critical parameters such as flow rates and chemical concentrations. Connect these sensors to a central controller that can process this data in real time.

-

Implement IoT Solutions

Integrate IoT technology to enable remote monitoring and control. Use cloud-based platforms to store and analyze data, allowing for more informed decision-making.

-

Train Your Staff

Provide training for staff to ensure they understand how to operate the automated system and respond to alerts effectively. This step is crucial for maximizing the benefits of automation.

-

Monitor and Optimize

Once your dosing system is automated, continuously monitor its performance. Use data analytics to identify areas for further optimization and make necessary adjustments to improve efficiency.

Automating dosing systems significantly enhances control, precision, and efficiency in industrial processes. By integrating IoT technologies, businesses can achieve real-time monitoring and data-driven decision-making, leading to improved dosing accuracy and reduced operational costs. As industries continue to evolve, embracing automation and IoT will be key to staying competitive and achieving long-term success.

For organizations looking to implement automated dosing solutions, investing in reliable technology and training is essential. By taking these steps, you can transform your dosing operations, ensuring optimal performance and compliance with industry standards.