Dosing pumps are essential tools in various industries, providing precise and controlled fluid delivery for a range of applications. To ensure these pumps operate reliably and efficiently for an extended period, proper maintenance is crucial. This comprehensive guide will provide you with best practices and valuable tips to keep your dosing pumps in top condition.

Understanding Dosing Pump Maintenance

Choosing the right dosing pump isn’t the only crucial step in ensuring its long-term reliability and efficiency. Dosing pump maintenance encompasses a series of activities designed to prevent breakdowns, optimize performance, and extend the lifespan of the pump. Regular maintenance can also help to identify potential issues early on, allowing for timely repairs and preventing costly downtime.

8 Maintenance Tips for Dosing Pumps

-

Routine Inspections

Regular inspections are the foundation of effective dosing pump maintenance. Make it a habit to visually inspect the pump and its surrounding area for signs of leaks, wear, or damage. Listen for any unusual noises during operation, as these could indicate potential problems.

-

Frequency

The frequency of inspections will depend on the pump’s operating conditions and the manufacturer’s recommendations. However, a general guideline is to perform inspections at least once a month.

-

Checklist

Create a checklist to ensure thorough inspections. Include items such as checking for leaks, inspecting tubing and fittings, examining the pump diaphragm or piston, and observing the pump’s overall condition.

-

-

Cleaning and Lubrication

Keeping the pump clean and properly lubricated is essential for smooth operation and preventing premature wear.

-

Cleaning

Clean the pump exterior regularly to remove dirt, dust, and chemical residue. Pay particular attention to areas where leaks may occur. Internal cleaning may also be necessary depending on the type of fluid being dosed and the manufacturer’s recommendations.

-

Lubrication

Lubricate moving parts according to the manufacturer’s instructions. Use the correct type and amount of lubricant to avoid over-lubrication, which can attract contaminants.

-

-

Calibration and Adjustment

Regular calibration and adjustment ensure accurate and consistent dosing.

-

Calibration

Calibrate the pump according to the manufacturer’s instructions and the specific requirements of your application. Calibration frequency will depend on the pump’s accuracy requirements and operating conditions.

-

Adjustment

Adjust the pump’s settings as needed to maintain the desired flow rate and pressure.

-

-

Diaphragm or Piston Replacement

The diaphragm or piston is a critical component of the dosing pump. Regular replacement is necessary to prevent leaks and maintain accurate dosing.

-

Replacement Interval

Refer to the manufacturer’s recommendations for the replacement interval. However, it is generally a good idea to replace the diaphragm or piston at least once a year or more frequently in demanding applications.

-

Inspection

Inspect the diaphragm or piston during routine maintenance for signs of wear, cracks, or tears. Replace it immediately if any damage is found.

-

-

Check Valves and Seals

Check valves and seals prevent backflow and ensure proper pump operation. Inspect these components regularly for wear or damage.

-

Inspection

Check valves and seals should be inspected during routine maintenance. Look for signs of wear, cracking, or hardening. Replace any damaged components promptly.

-

Cleaning

Clean check valves and seals to remove any debris or buildup that may affect their performance.

-

-

Tubing and Fittings

Inspect tubing and fittings regularly for signs of wear, cracks, or leaks. Replace any damaged components immediately.

-

Inspection

Examine tubing and fittings during routine maintenance. Pay close attention to areas where the tubing connects to the pump and other components.

-

Tightness

Ensure all fittings are properly tightened to prevent leaks.

-

-

Motor and Drive System

The motor and drive system power the pump. Regular maintenance of these components is essential for reliable operation.

-

Inspection

Inspect the motor and drive system for signs of wear, overheating, or unusual noises.

-

Lubrication

Lubricate the motor and drive system according to the manufacturer’s instructions.

-

Belt Tension

If the pump uses a belt drive, check the belt tension regularly and adjust it as needed.

-

-

Spare Parts and Inventory

Maintain an inventory of essential spare parts to minimize downtime in case of unexpected failures.

-

Critical Components

Keep spare parts for critical components such as diaphragms, pistons, check valves, seals, and tubing readily available.

-

Supplier Relationships

Establish good relationships with suppliers to ensure timely delivery of spare parts when needed.

-

3 Additional Tips For Maintenance

-

Record Keeping

Maintain detailed records of all maintenance activities, including inspections, repairs, and part replacements. This information can be valuable for troubleshooting and identifying recurring issues.

-

Training

Ensure personnel responsible for pump maintenance are adequately trained on proper procedures and safety protocols.

-

Manufacturer’s Recommendations

Always follow the manufacturer’s recommendations for maintenance and troubleshooting.

Proper maintenance is key to maximizing the lifespan and performance of your dosing pumps. By implementing these best practices and following a regular maintenance schedule, you can ensure your pumps operate reliably, efficiently, and safely for years to come. Remember, investing in preventive maintenance can save you significant time and money in the long run.

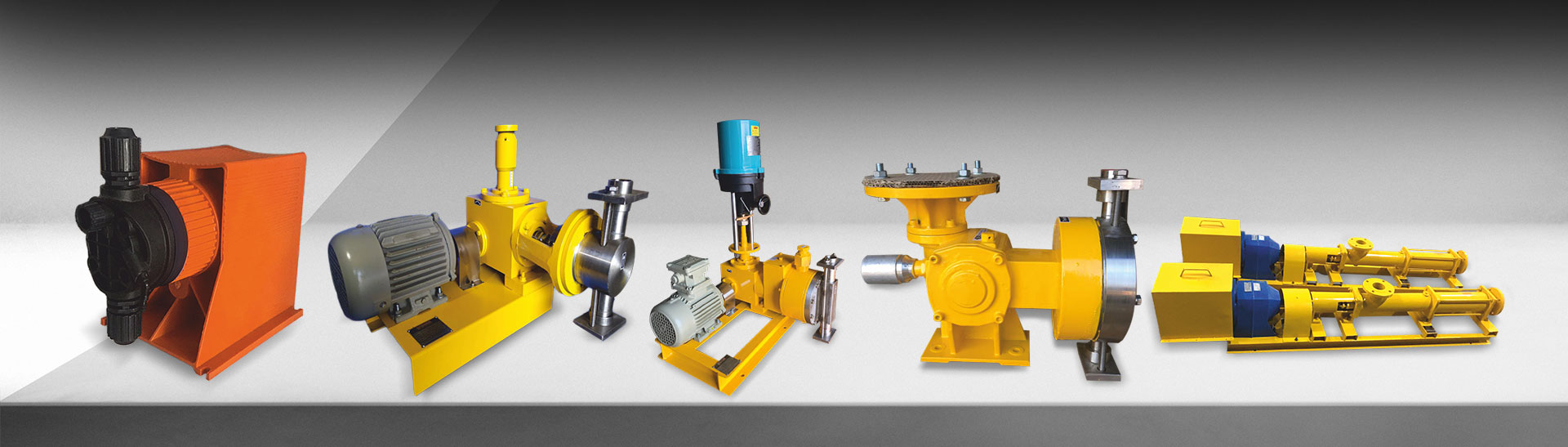

If you are seeking reliable dosing pump solutions for your industry, consider exploring the high-quality dosing pumps offered by Verito Engineering Pvt Ltd. Our extensive collection caters to various applications and industries, ensuring you find the perfect fit for your needs.