Quality dosing pumps are crucial to the chemical processing industry, where precise control over chemical dosages ensures product quality, safety, and compliance with environmental and safety regulations. In chemical processing, a minor deviation in quantity can significantly impact product outcomes or create safety risks. Dosing pumps deliver consistent, accurate dosages across various applications, from corrosion inhibition to pH balancing, making them essential for efficient, safe, and high-quality chemical production. Several prominent dosing pump manufacturers provide these critical solutions to meet industry standards and requirements.

Importance of Dosing Pumps in the Chemical Industry

Chemical processing requires precise and reliable control over fluid handling. Dosing pumps help regulate chemical dosages in applications that often involve hazardous or highly reactive substances. By automating and maintaining accuracy in chemical addition, dosing pumps help ensure operational safety and efficiency, reduce waste, and support sustainability initiatives. Additionally, they play a key role in optimizing production and maintaining compliance with stringent safety standards.

Applications of Dosing Pumps in Chemical Processing

Corrosion and Scale Inhibition

Dosing pumps deliver precise amounts of anti-corrosion agents and scale inhibitors to protect equipment, piping, and infrastructure from wear and tear, reducing maintenance costs and downtime.

pH Control and Neutralization

In many chemical processes, maintaining the right pH level is crucial for product quality, safety, and regulatory compliance. Dosing pumps help regulate pH by precisely adding acidic or alkaline substances to neutralize solutions. For instance, in wastewater treatment within chemical plants, dosing pumps are used to balance the pH before the water is discharged. This ensures that the effluent meets environmental standards and prevents damage to downstream equipment and infrastructure. Consistent pH control also helps in reducing the risk of corrosion and improves the stability of chemical reactions.

Water Treatment and Effluent Management

Dosing pumps are widely used in water treatment within the chemical industry, particularly for effluent management. They accurately add coagulants, flocculants, and other chemicals to remove suspended solids, heavy metals, and other contaminants from wastewater. In effluent treatment plants, dosing pumps are essential for processes like coagulation and flocculation, which help in binding particles together to ease their removal. This precise dosing minimizes chemical waste, reduces treatment costs, and ensures that the treated water meets regulatory standards. By effectively managing wastewater, chemical plants can maintain sustainable operations while reducing their environmental impact.

Catalyst and Reactant Addition

In chemical reactions, especially in industrial-scale production, catalysts and reactants need to be added in controlled amounts to optimize the reaction rates and ensure product quality. Dosing pumps are used to introduce these substances accurately into reactors, allowing manufacturers to control the pace and outcome of reactions. For instance, in polymer production or refining processes, adding just the right amount of catalyst can significantly improve yield and consistency. This precision is crucial in industries where even slight variations can affect the final product, such as in pharmaceuticals, petrochemicals, and specialty chemicals. Dosing pumps enable manufacturers to maintain consistency and efficiency by ensuring that catalysts and reactants are added in the optimal quantities.

Viscosity and Foam Control

Chemical processing often involves handling fluids with varying viscosities, which can impact flow rates and mixing. Dosing pumps are beneficial for managing these fluids, as they can handle a wide range of viscosities and accurately deliver specific amounts, regardless of the fluid’s thickness. In addition, many chemical reactions generate foam, which can reduce process efficiency and lead to equipment issues. Dosing pumps can add antifoaming agents to control and prevent foam buildup, ensuring smooth operations. This application is particularly important in sectors like food processing, pharmaceuticals, and petrochemicals, where foam can disrupt production lines. The ability of dosing pumps to adapt to fluids of different viscosities and control foam levels helps improve operational stability and efficiency.

Types of Dosing Pumps Commonly Used in Chemical Processing

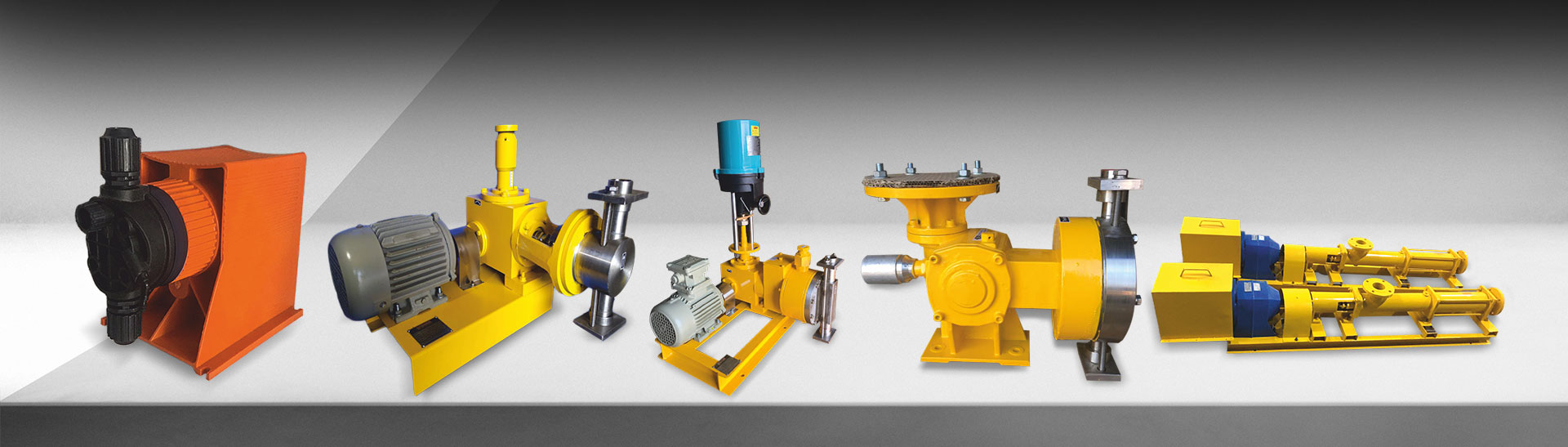

Diaphragm Pumps

Widely used in chemical applications due to their ability to handle corrosive, hazardous, and viscous substances with high accuracy. They provide leak-free performance, crucial for handling dangerous chemicals.

Piston Pumps

Suitable for high-pressure applications, piston pumps are known for delivering accurate doses of fluids, especially in cases where thick or highly viscous materials are involved.

Peristaltic Pumps

Ideal for handling sensitive or abrasive chemicals, peristaltic pumps are often preferred when maintaining purity and preventing contamination are necessary.

Each type offers unique advantages depending on the specific needs of the chemical processing task, such as flow rate requirements, fluid characteristics, and operational conditions.

Compliance and Safety Standards in Chemical Dosing

The chemical industry is heavily regulated to ensure safety and environmental compliance. Dosing pumps play a role in meeting these standards by providing controlled, precise chemical dosing to avoid over- or under-dosing, which can lead to safety risks or regulatory breaches. Key certifications like ATEX, FDA, and CE are often required, particularly in environments dealing with explosive or reactive chemicals. Additionally, the design of dosing pumps for chemical processing often incorporates features like leak detection and corrosion-resistant materials to handle harsh conditions.

Advantages of Using Dosing Pumps in Chemical Processing

Enhanced Operational Safety

Safety is paramount in chemical processing, where hazardous, corrosive, and sometimes toxic substances are handled. Dosing pumps enhance safety by minimizing the need for manual chemical handling, reducing the risk of spills, leaks, and operator exposure to harmful chemicals. Many dosing pumps are designed with features such as leak detection, automatic shut-off, and corrosion-resistant materials, which further safeguard workers and the environment. By automating dosing processes, companies can implement stricter safety protocols while ensuring compliance with industry regulations.

Improved Product Quality

In chemical manufacturing, maintaining precise chemical ratios is crucial for achieving consistent product quality. A slight variation in chemical quantities can lead to inferior or even unusable products, especially in sensitive applications like catalyst dosing or pH control. Dosing pumps deliver chemicals at accurate, programmable rates, allowing for fine-tuned adjustments based on production needs. This precision helps maintain the desired chemical composition, reaction rates, and end-product specifications, leading to higher customer satisfaction and fewer production defects.

Cost Efficiency

Precise dosing not only ensures consistency but also minimizes waste. Overdosing chemicals leads to unnecessary expenses, while underdosing can result in product reprocessing or disposal, both of which increase costs. Dosing pumps reduce these risks by delivering exact amounts, helping companies save on material costs. Additionally, with automated dosing, companies can optimize their chemical consumption, making the process more sustainable and cost-effective over time.

Environmental Compliance

Compliance with environmental regulations is critical in chemical processing, particularly regarding waste management and emissions. Dosing pumps play a key role in effluent treatment and wastewater management by adding neutralizing agents, coagulants, or other chemicals at precise concentrations. This controlled dosing ensures that discharge meets environmental standards, reducing the risk of harmful pollutants entering the ecosystem. Companies can avoid hefty fines and reputational damage associated with non-compliance by using dosing pumps to control and treat waste products effectively.

Key Considerations When Selecting a Dosing Pump for Chemical Processing

Choosing the right dosing pump for chemical applications involves evaluating factors such as pump material compatibility (corrosion and abrasion resistance), required flow rate, and the pump’s ability to handle chemical viscosities and concentrations. Special attention should be paid to certifications for hazardous environments and the ability of the pump to withstand varying pH levels, pressures, and temperatures commonly encountered in chemical processing environments.

Dosing pumps are invaluable assets in chemical processing, where safety, precision, and compliance are essential. From corrosion prevention to wastewater treatment, dosing pumps enable manufacturers to handle hazardous substances effectively while maintaining product quality and operational efficiency. Verito Engineering Pvt Ltd manufactures a range of high-performance dosing pumps tailored for chemical processing applications, providing reliable solutions that help companies meet stringent industry standards.