Mining and metals industries are among the most demanding sectors in terms of precision, efficiency, and safety in chemical handling. Dosing pumps play a pivotal role in meeting these demands, providing accurate control over the delivery of chemicals and additives essential to various processes. From ore processing and mineral extraction to wastewater treatment and corrosion control, dosing pumps enable mining and metals companies to streamline operations, reduce waste, and adhere to stringent environmental and safety regulations. This article explores the applications, advantages, and types of dosing pumps that support the mining and metals industry.

Key Applications of Dosing Pumps in Mining and Metals

Ore Processing and Flotation

Dosing pumps are crucial in ore processing, where precise amounts of chemicals such as flotation reagents, flocculants, and depressants are added to separate valuable minerals from ore. In flotation processes, chemicals modify the surface properties of particles, making it easier to isolate minerals from unwanted material.

The exact dosing of these chemicals is essential to achieve efficient separation, reduce chemical waste, and optimize mineral recovery. Dosing pumps ensure that reagents are added accurately, helping operators control the process for maximum yield.

pH Control and Acid Dosing

pH control is critical in various stages of mining and metal processing, particularly in hydrometallurgy, where metals are extracted using acid leaching. Maintaining the right pH level is vital for process efficiency and safety. Dosing pumps are used to add acids (like sulfuric acid) or alkalis to control pH levels in leaching solutions.

In addition to optimizing leaching, precise pH control reduces equipment corrosion and ensures compliance with environmental standards. Dosing pumps allow for consistent acid or base injection, stabilizing pH and protecting both the process and equipment.

Corrosion and Scale Inhibition

Mining environments are prone to corrosion, especially in areas with high humidity, abrasive particles, and harsh chemicals. Dosing pumps help mitigate corrosion by accurately delivering corrosion inhibitors into pipelines, tanks, and other metal surfaces.

Scale buildup is another common issue in mining, as minerals in water can accumulate and form deposits on equipment. Dosing pumps add anti-scaling agents, preventing scale buildup, enhancing equipment longevity, and reducing maintenance costs.

Wastewater Treatment and Effluent Management

Mining and metal processing generate large volumes of wastewater that often contain contaminants, heavy metals, and toxic chemicals. To meet regulatory standards, wastewater must be treated before being discharged.

Dosing pumps play a significant role in wastewater treatment by accurately dosing chemicals such as flocculants, coagulants, and neutralizers. These chemicals aid in separating solids from liquids, reducing contaminants, and adjusting pH levels. Dosing pumps ensure a controlled application, making the treatment process efficient and compliant with environmental guidelines.

Dust Suppression

Mining operations generate significant dust, which poses health risks and impacts air quality. Dosing pumps are used to add dust suppression agents to water systems, which are then sprayed to minimize airborne particles.

By precisely dosing dust control chemicals, dosing pumps enhance worker safety, reduce environmental impact, and improve visibility in mining sites.

Advantages of Dosing Pumps in the Mining and Metals Industry

Precision and Consistency

Dosing pumps are designed to deliver accurate, repeatable doses of chemicals, making them ideal for processes that require high precision. This consistency ensures that chemicals are applied in the correct amounts, minimizing waste and improving process outcomes.

Reduced Chemical Waste

Chemical costs are a significant factor in mining operations, and dosing pumps help reduce waste by applying only the necessary amount of reagents, inhibitors, and treatment chemicals. This not only lowers operational costs but also minimizes environmental impact.

Enhanced Equipment Lifespan

In mining, equipment is exposed to corrosive substances and abrasive materials. By accurately dosing corrosion inhibitors and anti-scaling agents, dosing pumps help protect equipment, prolonging its lifespan and reducing maintenance needs.

Improved Safety and Compliance

Mining and metals operations are heavily regulated due to the environmental and health risks associated with chemicals. Dosing pumps allow companies to manage these risks effectively, ensuring chemicals are handled safely and processes remain compliant with regulations.

Adaptability to Various Mining Applications

Dosing pumps are versatile and can handle a range of applications, from pH adjustment to dust suppression. Their ability to deliver chemicals in precise quantities across multiple processes makes them an indispensable asset in mining operations.

4 Challenges in Mining Dosing

Handling Abrasive and Corrosive Fluids

Mining and metals processing involve harsh chemicals that can damage equipment. Dosing pumps, particularly those with materials resistant to corrosion and abrasion, are built to handle these challenges, ensuring reliable performance over time.

Managing Large-Scale Operations

Mining sites are expansive, and dosing systems need to cover large areas and varying applications. Dosing pumps can be configured to integrate with centralized control systems, enabling automated, consistent chemical application across different locations.

Ensuring Environmental Compliance

Mining generates considerable waste and pollution. Dosing pumps help in managing effluents by delivering chemicals needed for wastewater treatment, ensuring the treated water meets environmental standards before discharge.

Meeting Demand for Consistent Production Quality

Fluctuations in chemical dosing can lead to inconsistent product quality in metal processing. Dosing pumps provide precise control over chemical inputs, allowing mining operations to maintain consistent quality in metal output.

Dosing pumps are essential components in the mining and metals industry, providing precise control over the addition of chemicals and additives critical to various processes. From ore flotation and pH control to wastewater treatment and corrosion prevention, these pumps ensure that mining operations are efficient, cost-effective, and environmentally compliant. By using dosing pumps, mining companies can achieve high levels of accuracy, reduce chemical waste, and maintain equipment longevity, contributing to safer and more sustainable operations.

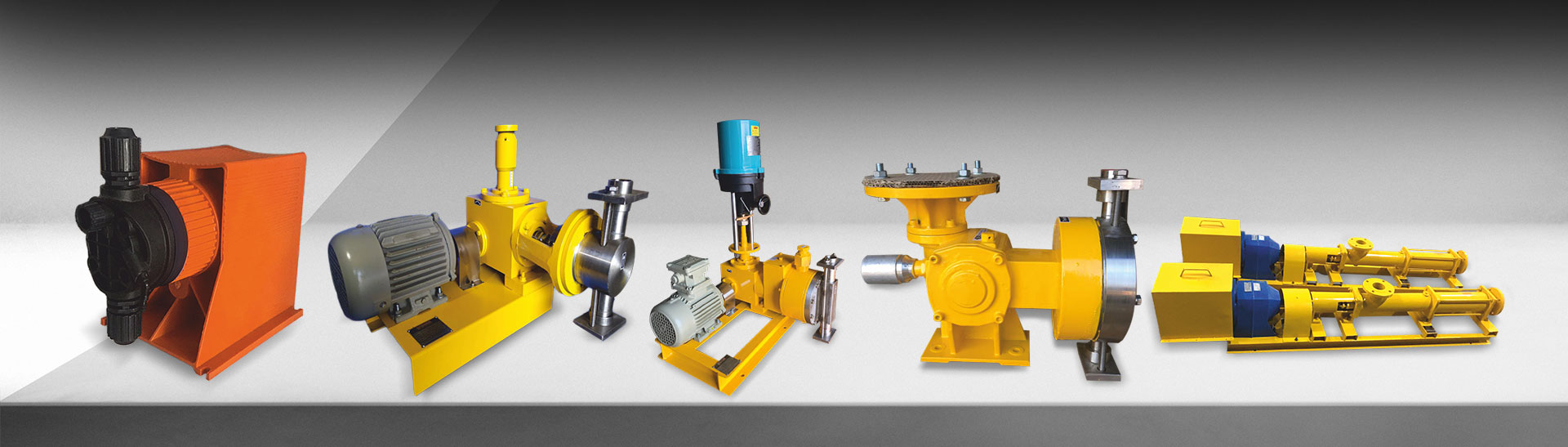

Verito Engineering Pvt Ltd, a leading dosing pump manufacturer, offers reliable and high-quality dosing pumps tailored to the needs of the mining and metals industry. Their dosing pumps are designed to handle the rigors of mining environments, delivering consistent performance across a wide range of applications, from ore processing to environmental management.