Water treatment is a crucial process that ensures the safe supply of clean water for domestic, industrial, and agricultural use. Dosing pumps play an integral role in water treatment systems by precisely injecting chemicals and additives into the water at specific rates. These chemicals could include disinfectants, coagulants, or pH regulators, which are vital for purifying water, making it safe for human consumption or industrial application.

In this article, we’ll explore the importance of dosing pumps in water treatment, the various applications, and the types of dosing pumps used, with a particular focus on how these systems ensure efficiency and accuracy in the water treatment process.

Importance of Dosing Pumps in Water Treatment

Dosing pumps are essential for maintaining the balance of water chemistry by introducing precise amounts of chemicals. These pumps offer several key advantages:

-

Accuracy and Precision

Dosing pumps are designed to inject chemicals at exact flow rates, which is critical for ensuring that the water is neither over- nor under-treated.

-

Automation

Many dosing pumps can be automated and integrated into larger water treatment systems, making them more efficient and reducing the need for manual intervention.

-

Safety

In scenarios where chemicals such as chlorine or sulfuric acid are used, dosing pumps ensure that only the required quantity is added, preventing any hazardous overuse.

-

Consistency

Dosing pumps provide a reliable and consistent method of adding chemicals, which is vital for continuous water treatment processes, especially in industrial setups.

6 Applications of Dosing Pumps in Water Treatment Systems

Dosing pumps are used in various phases of water treatment, addressing different requirements. Below are some of the most common applications:

-

pH Control

One of the primary applications is controlling the pH level in water. Chemicals like sulfuric acid or sodium hydroxide are injected into the water to maintain the pH within an optimal range. Maintaining the correct pH level is crucial for both potable water and wastewater treatment, as improper pH can lead to corrosion or poor performance of the water treatment system.

-

Disinfection

Dosing pumps are also used to add disinfectants like chlorine or sodium hypochlorite to water. This is especially important in municipal water treatment plants where it’s necessary to kill harmful bacteria and pathogens. The dosing must be accurate to ensure water safety without over-chlorination, which can result in harmful by-products.

-

Coagulation and Flocculation

In the water purification process, coagulation chemicals (like alum) are added to aggregate impurities so that they can be easily removed. Dosing pumps help introduce these coagulants at precise levels, optimizing the coagulation and flocculation processes.

-

Wastewater Treatment

Dosing pumps are extensively used in wastewater treatment plants for introducing chemicals that facilitate sludge breakdown, odor control, and nutrient removal. For instance, phosphorus removal in wastewater is often achieved through chemical dosing.

-

Desalination Plants

In desalination processes, dosing pumps are critical for adding anti-scaling agents to prevent the build-up of deposits on membranes, ensuring that the desalination process runs smoothly and efficiently.

-

Cooling Towers and Boilers

Industrial applications of water treatment often involve cooling towers and boilers where dosing pumps are used to add corrosion inhibitors, anti-scaling chemicals, and biocides to protect the infrastructure from damage caused by untreated water.

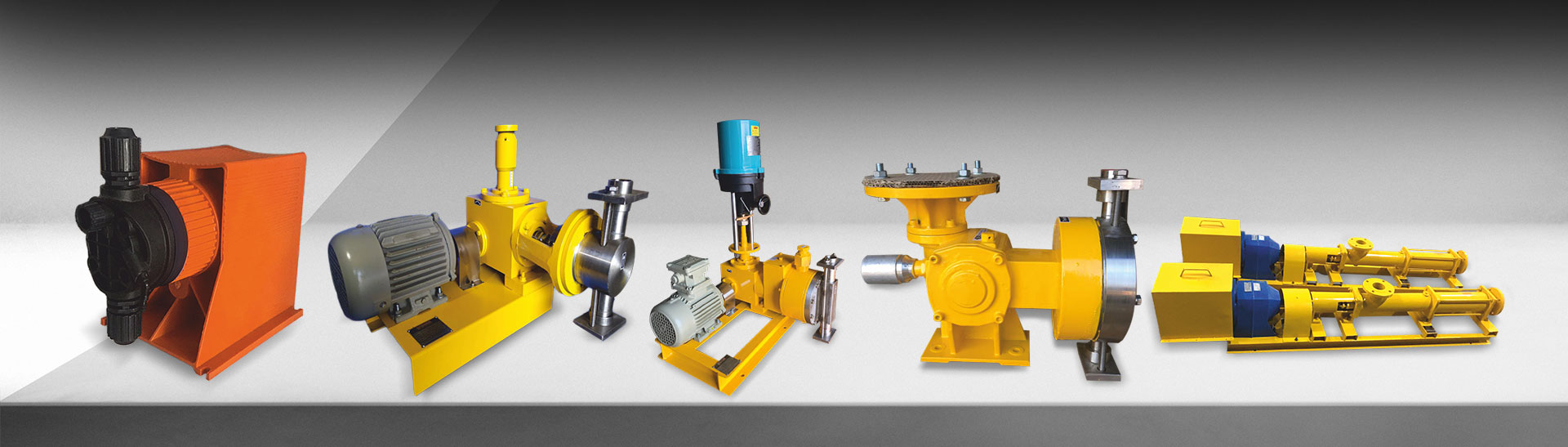

5 Types of Dosing Pumps in Water Treatment Systems

Depending on the application and requirements, different types of dosing pumps are used in water treatment systems. Below are the most common types:

-

Electronic Metering Pumps

Electronic Metering Pumps are widely used due to their accuracy and ease of integration with automated systems. They offer a wide range of flow rates and are commonly used in disinfection and pH control applications.

-

Plunger Metering Pumps

Known for their high-pressure capabilities, plunger metering pumps are ideal for applications requiring the injection of chemicals into high-pressure environments, such as in desalination plants.

-

Diaphragm Pumps

Diaphragm pumps, which can be hydraulically or mechanically operated, are known for their reliability and ability to handle chemicals that are abrasive or contain solid particles. These pumps are often used in both drinking water and wastewater treatment plants.

-

Peristaltic Pumps

These pumps are particularly useful when dealing with chemicals that are sensitive to contamination or require a sealed system. The liquid is kept completely isolated from pump components, making peristaltic pumps ideal for dosing chlorine or fluorine in municipal water systems.

-

Solenoid Pumps

Solenoid pumps use electromagnetic force to create the pumping action. These pumps are often used for small-scale dosing applications, such as in residential water treatment systems, where precise chemical dosing is essential.

4 Advantages of Using Dosing Pumps in Water Treatment Systems

-

Customizable Flow Rates

Dosing pumps offer adjustable flow rates, making it easier to control the exact amount of chemicals needed based on the specific treatment requirements.

-

Durability

High-quality dosing pumps are built to withstand harsh chemical environments and high-pressure systems, making them reliable and long-lasting.

-

Cost-Efficiency

By precisely controlling the amount of chemicals used, dosing pumps help reduce waste and lower operating costs in water treatment facilities.

-

Environmental Impact

Dosing pumps ensure that harmful chemicals are not excessively released into water systems, minimizing the environmental impact of water treatment operations.

Dosing pumps are an indispensable part of water treatment systems, providing the precision, safety, and efficiency needed to ensure that water is treated effectively. From municipal water treatment plants to industrial applications like cooling towers and desalination, the role of dosing pumps spans various sectors and processes.

With advancements in automation and digital integration, dosing pumps continue to evolve, offering better control and optimization for water treatment systems. Verito Engineering Pvt Ltd, one the best manufacturers of reliable dosing pump in India, caters to diverse water treatment needs by manufacturing efficient dosing pumps. Whether you’re dealing with pH control, disinfection, or wastewater treatment, dosing pumps provide the accuracy and reliability needed to maintain water quality.

As you look to improve your water treatment processes, consider leveraging Verito Engineering’s dosing pumps for their unparalleled performance and longevity.