Get Your Free Quote…!

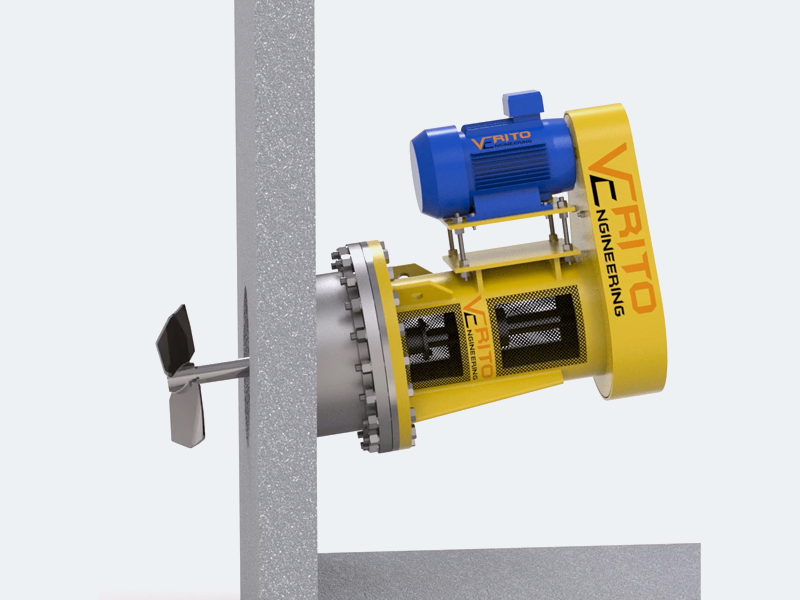

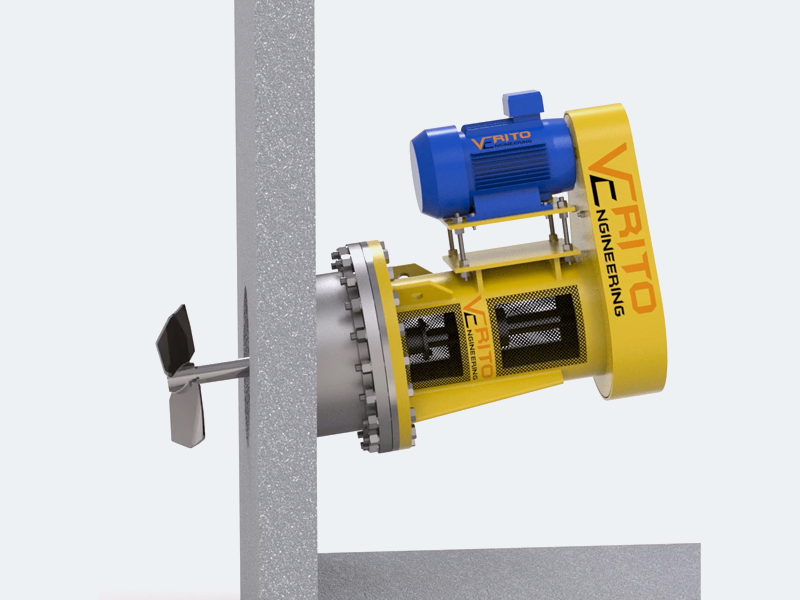

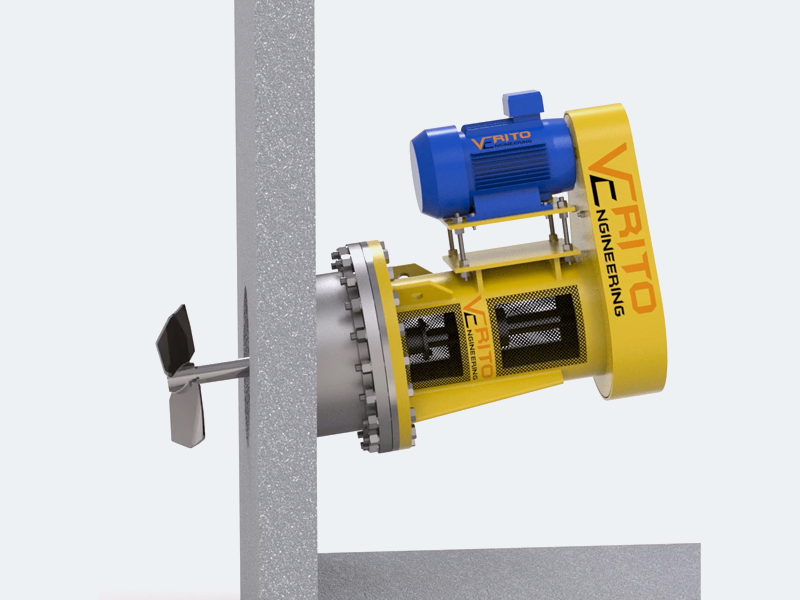

Verito is at the forefront of innovation in the design and manufacture of side entry agitators, specifically tailored for biogas plant digestor tanks. Our agitators are engineered to meet the rigorous demands of biogas production, where the efficiency of organic material digestion directly impacts gas yield and overall plant performance. With a commitment to quality, precision, and durability, Verito’s side entry agitators are the ideal solution for optimizing the mixing process within digestor tanks, ensuring consistent and reliable biogas production.

Advanced Engineering for Optimal Mixing

At the heart of Verito’s side entry agitators is our advanced engineering approach. Each agitator is meticulously designed to achieve optimal mixing within the digestor tank, ensuring that the slurry of organic material is evenly distributed and adequately homogenized. This is crucial for maintaining consistent temperatures and promoting efficient microbial activity, which are key factors in maximizing biogas yield

Key Technical Features

Application in Biogas Plant Digestor Tanks

In biogas plants, the digestor tank is the core of the operation where organic materials are broken down anaerobically to produce biogas. Efficient mixing is critical to maintaining optimal conditions for microbial activity, which in turn influences the rate of digestion and the volume of biogas produced. Verito’s side entry agitators are specifically engineered to enhance these processes by ensuring uniform distribution of heat, nutrients, and microorganisms throughout the digestor.

Benefits of Verito Side Entry Agitators

| Motor Power | Upto 30 kW |

| % Solid Concentration | 0-10% (W/W) |

| Impeller Diameter | 300mm – 1000mm |

| Shaft Diameter | 30-100 mm |

| Shaft Sealing | Mechanical Seal with Shutt Off Arrangement |

| Impeller Type | Hydrofoil, Wide Foil, Turbine |

| Materials (Wetted Parts) | SS304, SS316 or Better Grade |

Verito’s side entry agitators are the product of decades of experience and expertise in the field of industrial mixing solutions. We are committed to delivering high-performance equipment that meets the specific needs of biogas plant operators. Our focus on innovation, quality, and customer satisfaction ensures that you receive an agitator that not only meets but exceeds your expectations.

When you choose Verito, you are investing in a solution that enhances the efficiency and productivity of your biogas plant, contributing to a more sustainable and profitable operation.

Trust Verito to be your partner in achieving superior results in biogas production.