Get Your Free Quote…!

Purpose: Diesel Dosing System is to reduce nitrogen oxide emissions in diesel engines by precisely injecting small amounts of diesel exhaust fluid (DEF) into the exhaust stream.

Overview: A diesel dosing system is a component used in diesel engines to precisely meter and inject small amounts of diesel exhaust fluid (DEF) into the exhaust stream. DEF is a solution of urea and deionized water that is injected into the exhaust gas to reduce nitrogen oxide (NOx) emissions. The dosing system consists of a pump, injector, control module, and sensors that work together to accurately measure and inject the right amount of DEF at the right time.

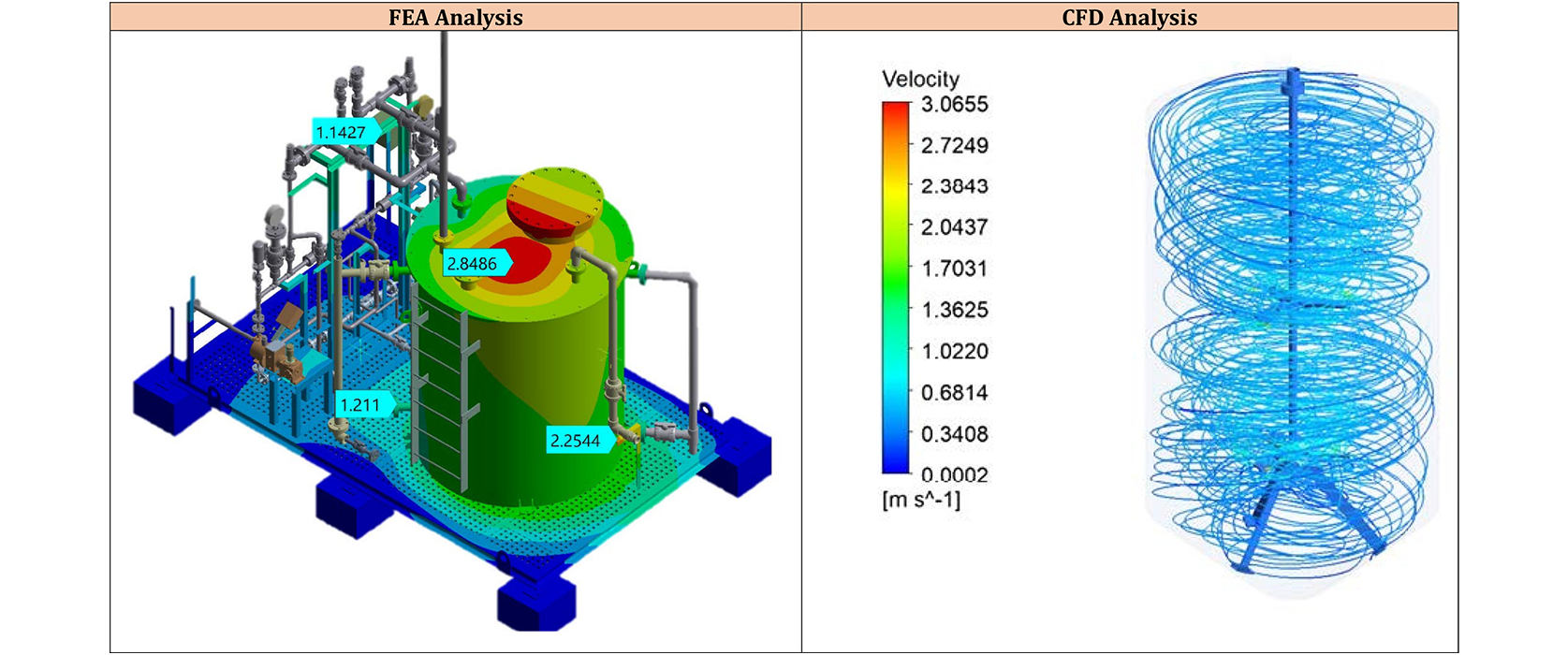

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

The dosing system typically operates in a closed-loop control system, where sensors monitor the NOx levels in the exhaust gas and send signals to the control module. The control module then adjusts the flow rate of DEF based on the NOx levels, ensuring that the engine is operating within emissions regulations. The dosing system can also be integrated with other engine management systems, such as the fuel injection system and the engine control unit, to optimize engine performance and reduce emissions.

Diesel dosing systems are commonly used in heavy-duty diesel engines, such as those used in commercial trucks, buses, and off-road vehicles. They are an essential component of modern diesel engines, helping to meet emissions regulations while maintaining engine performance and fuel efficiency.

Supplied to:Oil & Gas Industry, UAE

Technical Aspects: Available in ATEX, CE, ASME, API, IS…..etc.