Get Your Free Quote…!

The KOH (Potassium Hydroxide) Circulation System designed and engineered by Verito Engineering Private Limited plays a crucial role in the electrolyser-based Green Hydrogen Production Project. This high-precision system is responsible for circulating and controlling KOH solution within the electrolyser setup to ensure efficient hydrogen production through electrolysis of water.

Overview: The KOH Circulation System is a fully automated system designed to circulate and regulate the potassium hydroxide solution between the electrolyser cells and associated components. Its key function is to maintain the electrolyte's concentration, flow rate, and temperature, optimizing the performance of the electrolysers for sustainable hydrogen generation.

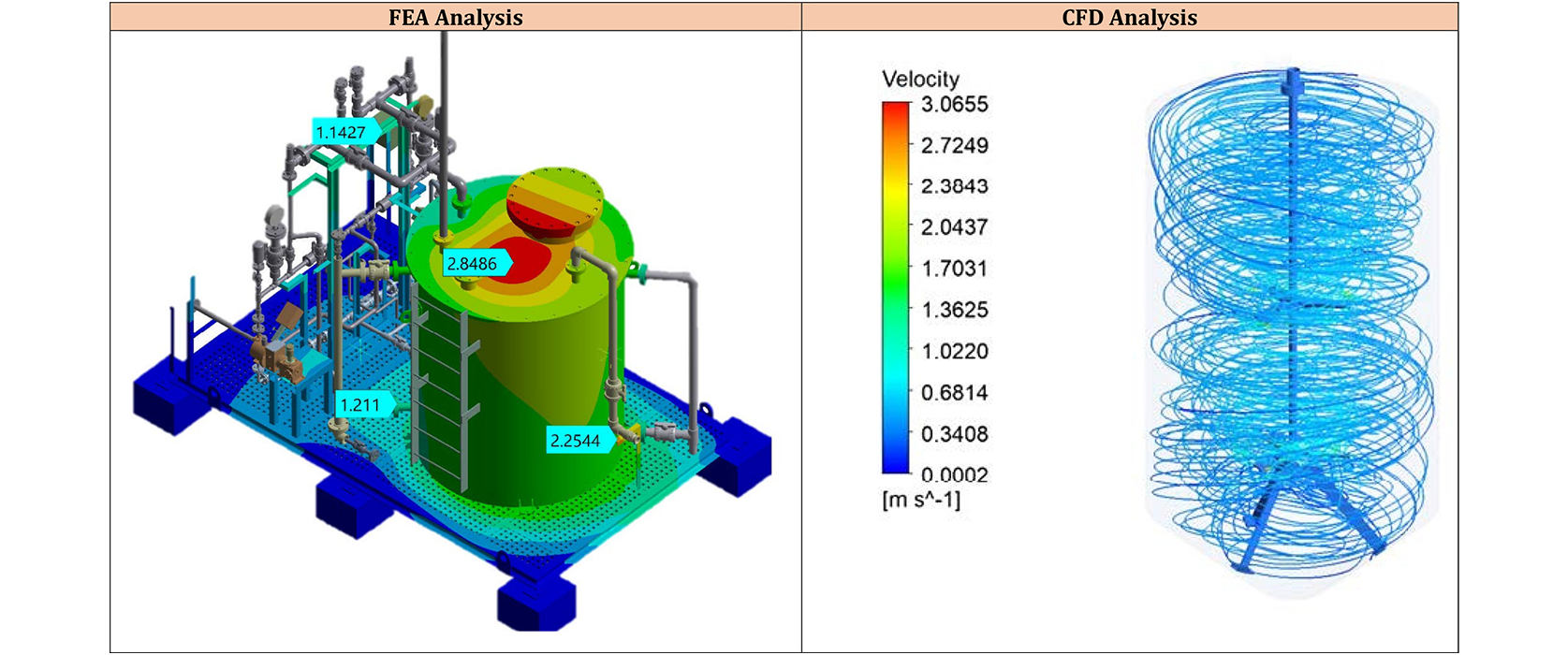

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

Key Features and Benefits

The KOH Circulation System is integral to the alkaline water electrolysis process, where potassium hydroxide acts as the electrolyte. The continuous circulation of KOH ensures:

| Material of Construction | SS316L / Duplex Stainless Steel for wetted parts |

| Flow Rate | Customizable as per application needs (standard range: 0.5 to 5 m³/h) |

| Pump Type | Magnetic drive pumps and diaphragm metering pumps for precise fluid handling |

| Operating Pressure | Up to 10 bar |

| Temperature Range | 20°C to 80°C, with integrated temperature control via heat exchangers |

| Control System | PLC-based with HMI interface for real-time monitoring and adjustments |

| Electrical Requirements | 400V, 50Hz, 3-phase |

| KOH Concentration | Adjustable concentration levels, typically in the range of 20-30% for electrolyser applications |

Advantages

Although primarily designed for use in L&T’s Green Hydrogen Production project, the KOH Circulation System can be adapted for other applications, such as chemical processing, fuel cell electrolyte management, and wastewater treatment systems.