Get Your Free Quote…!

The Containerized Chemical Dosing System by Verito Engineering Private Limited is a pre-engineered, fully integrated, plug-and-play chemical dosing package housed within a robust ISO container. It is designed to simplify site installation, enhance safety, and enable efficient chemical storage, preparation, and dosing across various industries.

This modular system is ideal for locations with space constraints, remote project sites, or hazardous chemical handling zones. The entire dosing infrastructure—including chemical storage tanks, preparation units, metering pumps, automation panels, ventilation, and safety systems—is factory-fabricated, pre-tested, and delivered as a self-contained unit, ready for rapid deployment and commissioning at the site.

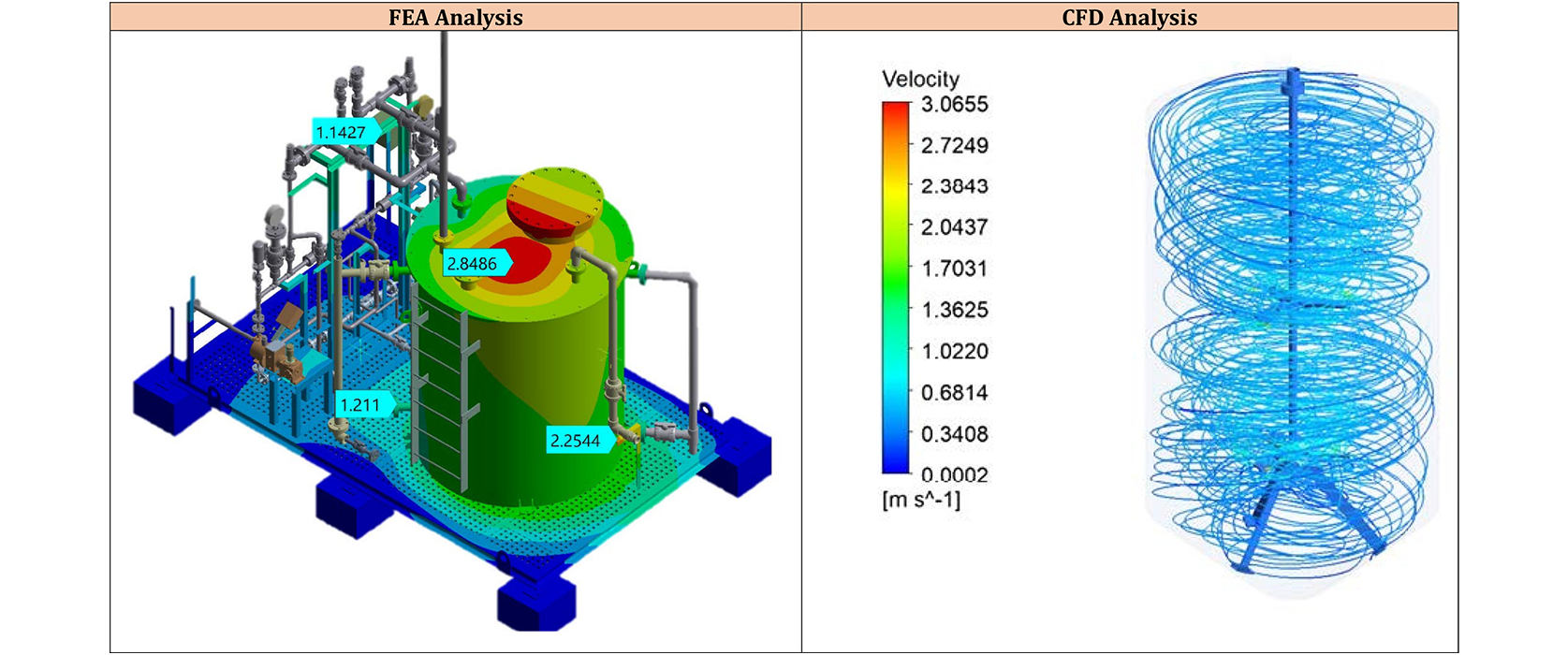

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

| Feature | Details |

|---|---|

| Type | ISO Shipping Container (CSC Certified) |

| MOC | Mild Steel with Anti-Corrosive Epoxy Paint / Stainless Steel Cladding |

| Flooring | FRP Grating over Chemical-Resistant Bund Tray |

| Insulation | Mineral Wool / PUF Panels (Optional for Temperature Control) |

| Access | Double Doors with Safety Locks, Emergency Exit (Optional) |

| Lighting | Flameproof / Weatherproof LED Lighting |

| Ventilation | Exhaust Fans with Ducts & Chemical Filters |

| Feature | Details |

|---|---|

| Tank Capacity | 500 L to 20,000 L (as per requirement) |

| Tank MOC | HDPE / PP / FRP / SS316 based on chemical compatibility |

| Level Instrumentation | Radar / Ultrasonic / Float Type |

| Agitators | Top-Mounted Helical / Anchor / Hydrofoil (if required for mixing) |

| Feed Water System | With Flow Control Valve & Meter |

| Powder Handling | Hopper with Screw Feeder & Vibrator for Powder Chemical Mixing |

| Feature | Details |

|---|---|

| Pump Type | Solenoid Diaphragm / Motorized Diaphragm / Plunger Pumps |

| Flow Range | 0.5 LPH to 51000 LPH (Customizable) |

| Pressure Rating | Up to 50 Bar (Higher on request) |

| Pump MOC | SS316 / PTFE / PVC / Hastelloy based on chemical |

| Accessories | Pulsation Dampeners, PRV, NRV, Isolation Valves, Calibration Columns |

| Control | Manual / VFD / PLC Controlled Flow Adjustment |

| Redundancy | Duty + Standby Pump with Auto Changeover (Optional) |

| Feature | Details |

|---|---|

| Control Panel | MS Powder Coated / SS304 IP65 Panel with Internal Wiring |

| PLC & HMI | Siemens / Schneider / Allen Bradley with 7" or 10" HMI |

| Connectivity | Ethernet / MODBUS / PROFIBUS / IoT Ready |

| Safety Alarms | Low Level, Dry Run, High Pressure, Emergency Stop |

| SCADA / Remote Monitoring | Optional via GSM / Wi-Fi / Cloud Platform |

| Parameter | Specification |

|---|---|

| Control Panel | SS304 / MS Powder Coated with Internal Wiring |

| PLC Make | Siemens / Schneider / Allen Bradley / Delta (as per client preference) |

| HMI | 7” or 10” Touchscreen – Password Protected |

| Communication | MODBUS / PROFIBUS / Ethernet / SCADA / IoT (Optional) |

| Alarm & Interlock | Buzzer + Indicator + System Shutdown |

| Data Logging | USB/SD Card or Remote Access |

| Feature | Details |

|---|---|

| Eyewash & Safety Shower | Floor-Mounted or Wall-Mounted |

| Spill Containment | Full-Length Bund with Leak Detection |

| Fire Detection System | Smoke / Heat Detector with Alarm |

| HVAC (Optional) | For temperature-sensitive chemicals |

| Exhaust System | ATEX Rated Motor with Chemical Fume Extraction |

Advantages