Get Your Free Quote…!

Verito Engineering Private Limited’s Additive Chemical Injection Package, developed for Tata Chemical Limited, is an advanced and high-precision system designed to dose and regulate chemical additives in various processes within chemical production. This system is engineered to meet the demanding requirements of industrial dosing, ensuring accuracy, efficiency, and safety across a wide range of applications.

Overview: The Additive Dosing System is a critical component in the chemical production process, where it ensures the precise addition of various chemical additives to achieve desired reactions, product qualities, or process optimization. Tailored to meet the specific needs of Tata Chemical Limited, this system is designed for accuracy, consistency, and long-term reliability, even in harsh industrial environments.

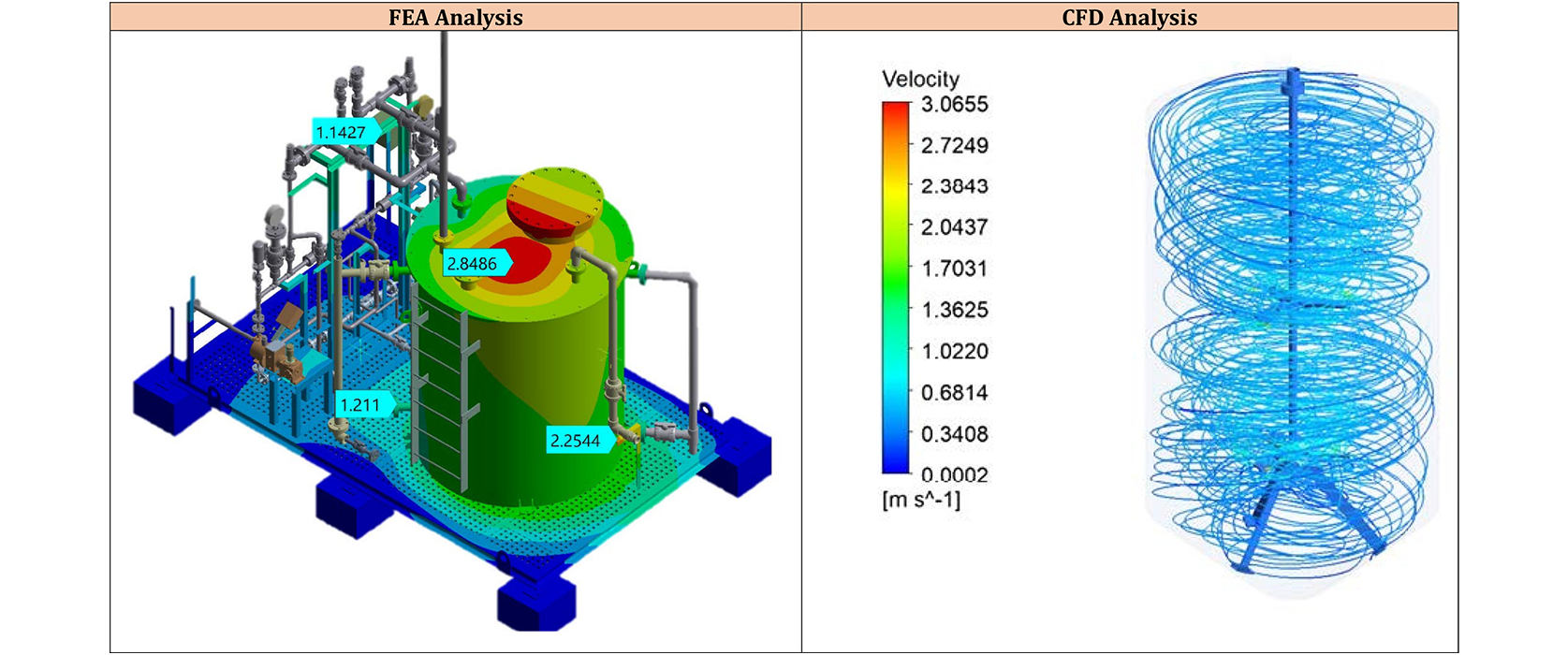

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

Key Features and Benefits

The Additive Dosing System is critical for controlling the introduction of chemical additives in processes such as

| Material of Construction | SS316L, Hastelloy, PTFE (depending on the chemical properties of the additive) |

| Pump Types | Plunger, Diaphragm, Hydraulic Diaphragm (customized as per application needs) |

| Flow Rate | Customizable to meet process requirements (ranging from 0.1 LPH to 1000 LPH) |

| Pressure Range | Capable of operating at pressures up to 100 bar |

| Control System | PLC-based with HMI interface, remote monitoring capabilities |

| Temperature Range | Up to 150°C (optional with temperature control) |

| Accuracy | ±0.5% to ±1% depending on process requirements |

| Electrical Requirements | 230V/400V, 50Hz, 3-phase |

While developed for Tata Chemical Limited, the Additive Dosing System can also be used in other industries such as pharmaceuticals, petrochemicals, food processing, and wastewater treatment, where precise and reliable chemical dosing is essential.