Get Your Free Quote…!

Purpose: LP dosing systems in power plants inject precise amounts of chemicals into the water-steam cycle to remove dissolved oxygen, control pH levels, and prevent corrosion in boilers, turbines, and condensers.

Overview: LP dosing systems are widely used in power plants to inject precise amounts of chemicals into the water-steam cycle. These systems are critical for maintaining the performance and reliability of power plant equipment, including boilers, turbines, and condensers.

The chemicals that are typically dosed in power plant LP dosing systems include oxygen scavengers, corrosion inhibitors, and pH control agents. Oxygen scavengers are used to remove dissolved oxygen from the feedwater, which can cause corrosion in the boiler and other equipment. Corrosion inhibitors are used to protect the metal surfaces from corrosion. pH control agents are used to maintain the desired pH level in the water-steam cycle, which is important for preventing corrosion and other issues.

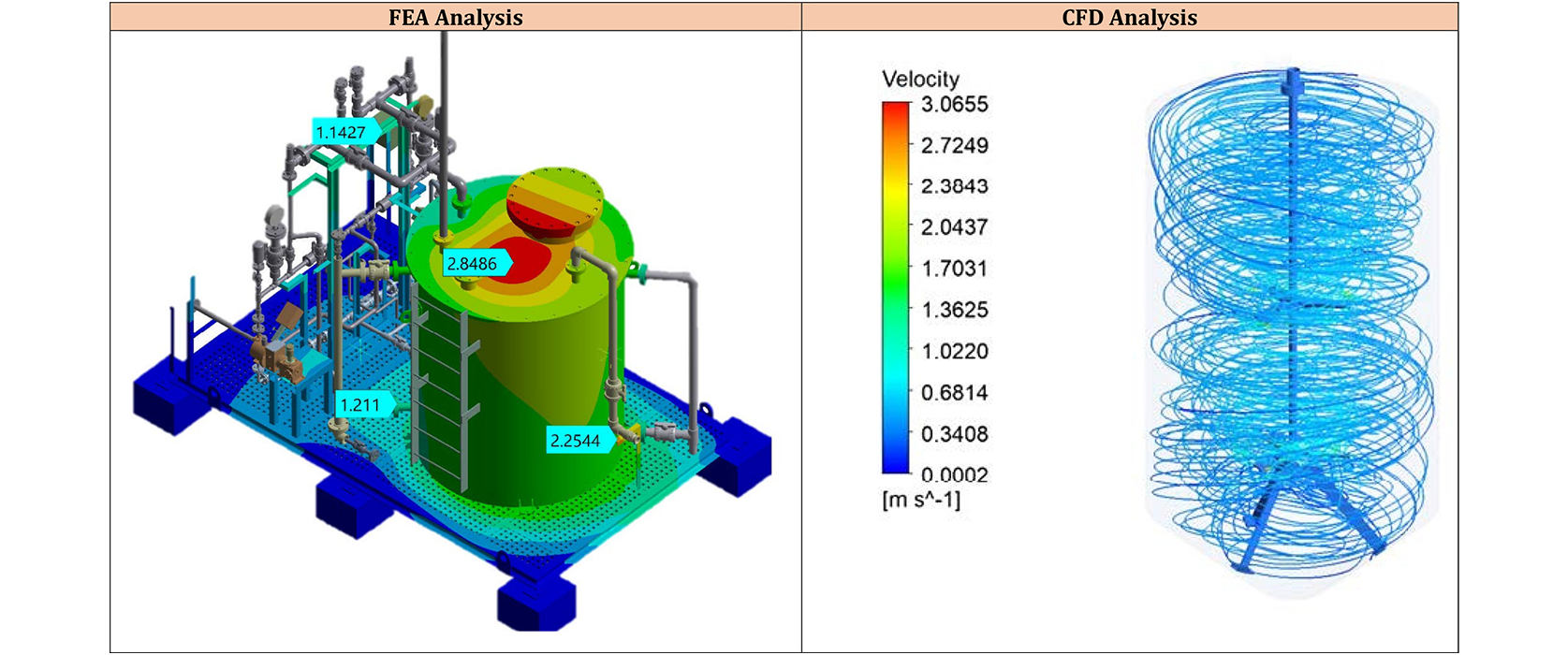

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

LP dosing systems in power plants typically consist of a chemical storage tank, a dosing pump, and a control system. The dosing pump is used to inject the chemical into the water-steam cycle at a precise flow rate, and the control system ensures that the dosing pump operates at the correct rate and provides feedback on the amount of chemical being dosed.

LP dosing systems are critical for maintaining the integrity and reliability of power plant equipment, and they play an important role in ensuring the safety and efficiency of power generation.

>Supplied to:

1. World’s One of the Top Multi-national Company in the

Beverage Industries.

2. One of India's biggest aluminum manufacturing company and the world's largest flat-rolled products player and recycler of aluminum

3. India’s Leading power plant company with a combined capacity of 1,391 MW

Project:

1. Coca-Cola Company.

2. Hindalco

3. JSW

4. Wacot Rice,

Nigeria (Thermax)

Technical Aspects: Available in ATEX, CE, ASME, API, IS…..etc.