Get Your Free Quote…!

Purpose: Octane Booster Dosing System is to increase the octane rating of gasoline by injecting octane booster additives into the fuel stream in a controlled and precise manner, typically in industrial settings where gasoline needs to be blended to meet specific octane requirements. .

Overview: An Octane Booster Injection Skid is a type of fuel blending system that is used to inject octane booster into gasoline. This skid-mounted system is typically used in fuel refineries, petrochemical plants, and other industrial settings where gasoline needs to be blended to meet specific octane requirements.

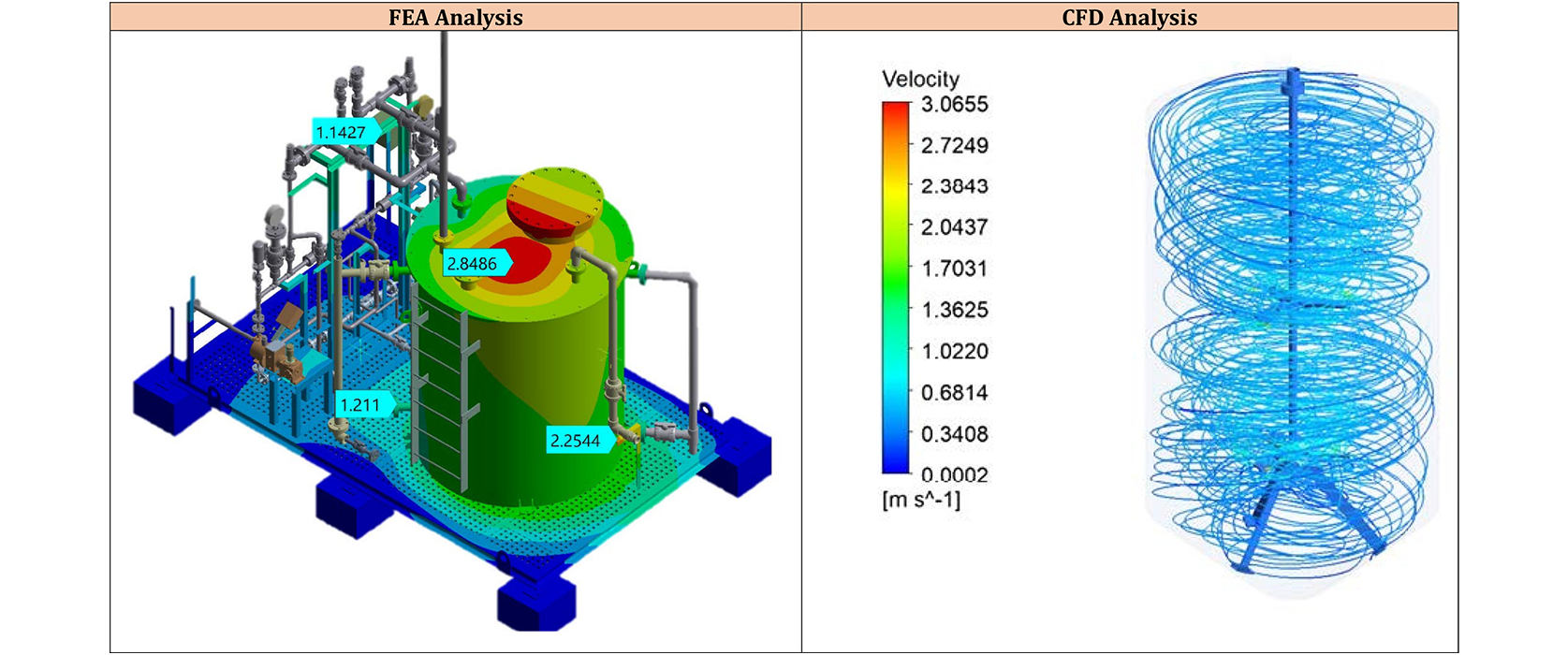

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

The Octane Booster Injection Skid typically includes a number of components, including a storage tank for the octane booster additive, pumps, valves, and control systems for metering the additive into the gasoline stream. The system may also include filters and other equipment to ensure that the blended gasoline meets quality standards.

The use of an Octane Booster Injection Skid can help fuel producers to optimize the octane rating of their gasoline blends, which can improve engine performance and reduce emissions. The system can also help to ensure consistent and accurate blending of gasoline, which is important for meeting quality standards and regulatory requirements.

Project: SRS Energy Limited

Technical Aspects: Available in ATEX, CE, ASME, API, IS…..etc.