Get Your Free Quote…!

Purpose: The purpose of the C Polymer Auto Dissolving Dosing System is to automate the precise dosing of polymer substances into water treatment processes, ensuring efficient and effective removal of impurities for enhanced water quality. .

Overview: Verito’s Polymer Auto Dissolving Dosing System is a sophisticated Injection Package designed for precise and efficient dosing of polymers in water treatment processes. Polymers play a crucial role in various water treatment applications, including flocculation, coagulation, and sedimentation, where they aid in the removal of suspended particles, organic matter, and other impurities from water.

The C Polymer Auto Dissolving Dosing System automates the process of dissolving polymer substances into water, ensuring accurate dosing levels and consistent performance. This system is particularly beneficial in industrial and municipal water treatment plants, where large volumes of water need to be treated efficiently and effectively.

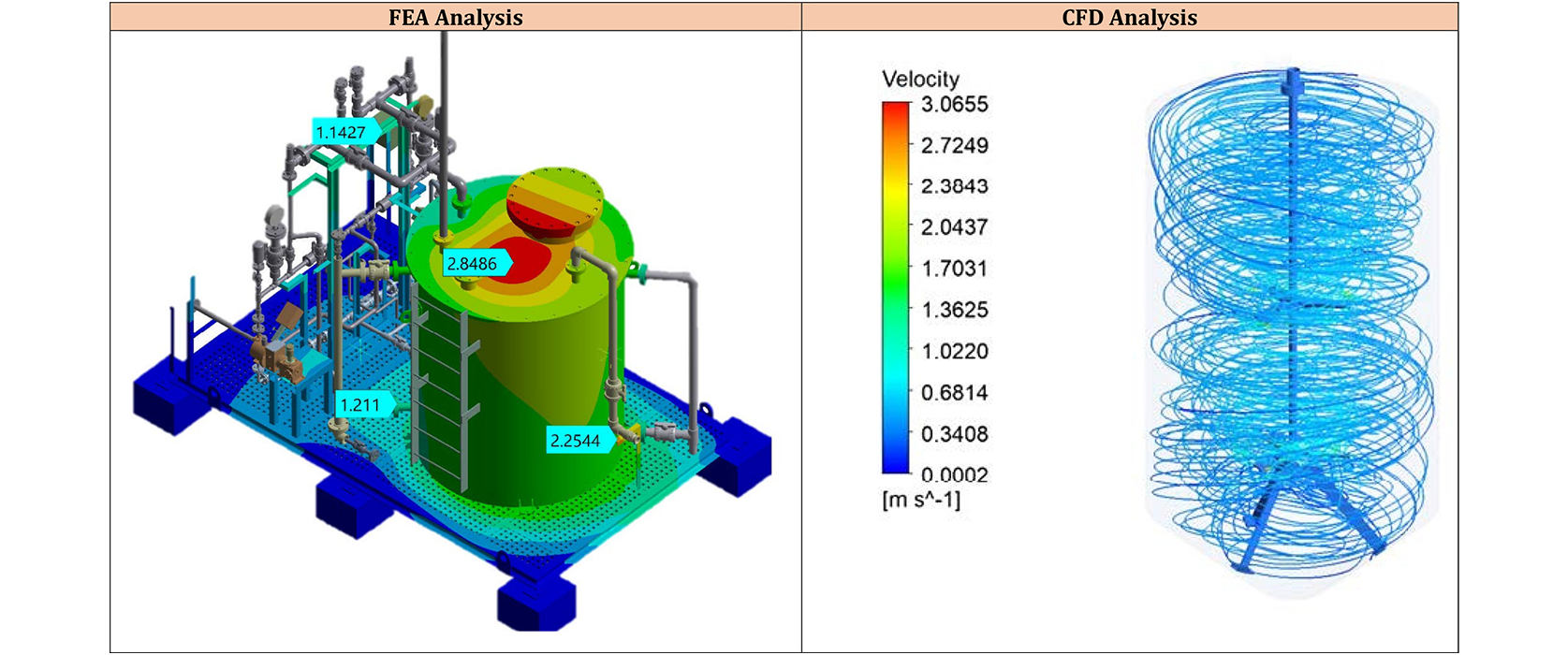

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

Key components of the C Polymer Auto Dissolving Dosing System typically include:

1. Polymer Dissolution Unit: This unit is responsible for dissolving polymer powder or liquid into water to create a homogeneous solution. It may utilize various mechanisms such as mixing, agitation, and hydration to facilitate rapid and thorough dissolution of the polymer.

2. Dosing Pump: The dosing pump precisely delivers the dissolved polymer solution into the water treatment process at the desired flow rate and concentration. This ensures accurate dosing and uniform distribution of the polymer throughout the water.

3. Control System: The control system regulates the operation of the dosing system, allowing users to set parameters such as dosing rate, concentration, and dosing schedule. Advanced control systems may incorporate features such as programmable logic controllers (PLCs) or SCADA (Supervisory Control and Data Acquisition) systems for automated control and monitoring.

4. Safety Features: Safety features such as pressure relief valves, leak detection sensors, and emergency shut-off mechanisms may be incorporated into the system to ensure safe operation and mitigate potential hazards.

5. User Interface: A user-friendly interface allows operators to monitor and control the dosing system easily. This interface may include a touchscreen display, push-button controls, and visual indicators for status feedback.

The use of an Polymer Auto Dissolving Dosing System Injection Skid can help fuel producers to optimize the octane rating of their gasoline blends, which can improve engine performance and reduce emissions. The system can also help to ensure consistent and accurate blending of gasoline, which is important for meeting quality standards and regulatory requirements.

Benefits of the C Polymer Auto Dissolving Dosing System with SCADA HMI Control Panel:

Optimize Polymer Usage: By precisely monitoring and controlling dosing, you can minimize polymer waste and ensure cost-effective operation

Maintain Consistent Performance: Real-time data insights allow you to proactively address potential deviations and maintain consistent polymer concentrations.

Simplify System Management: The intuitive interface simplifies system operation and troubleshooting, reducing training requirements for operators.

Improve Process Efficiency: Data-driven insights from the SCADA HMI can guide process improvements for enhanced efficiency and productivity.

Enhanced User Experience: The SCADA HMI control panel offers a graphical interface for easy system operation, configuration, and monitoring.

Real-Time Monitoring: View key system parameters such as polymer levels, dosing rates, and mixing status in real-time, allowing for proactive adjustments.

Precise Control: Fine-tune dosing parameters directly through the control panel, ensuring optimal polymer usage and consistent results.

Data Logging and Reporting: The system automatically logs operational data, enabling you to generate reports for process analysis and optimization.

Improved Troubleshooting: The SCADA HMI facilitates easier identification and diagnosis of potential system issues.

For more information:

To learn more about the C Polymer Auto Dissolving Dosing System with SCADA HMI Control Panel and how it can benefit your operations, please contact Verito Engineering Private Limited. Our experienced team is happy to answer your questions and provide you with a customized quote.