Get Your Free Quote…!

The Auto Polyelectrolyte Preparation & Dosing Package by Verito is a fully automated, skid-mounted system designed for efficient preparation and precise dosing of polymers used in water and wastewater treatment. Featuring a gravity-fed dual-tank design with the Preparation Tank mounted above the Dosing Tank, it eliminates the need for transfer pumps while ensuring consistent solution quality. Integrated with a PLC-HMI based control system, accurate screw feeder, and high-efficiency agitator, the system ensures reliable operation with minimal human intervention—making it ideal for applications like sludge dewatering, clarifier dosing, and effluent treatment.

This dual-level system features a Preparation Tank mounted above the Dosing Tank, enabling gravity-assisted transfer of the matured solution, ensuring consistent flow without transfer pumps. It supports continuous and batch-type operation, making it adaptable for both small- and large-scale requirements.

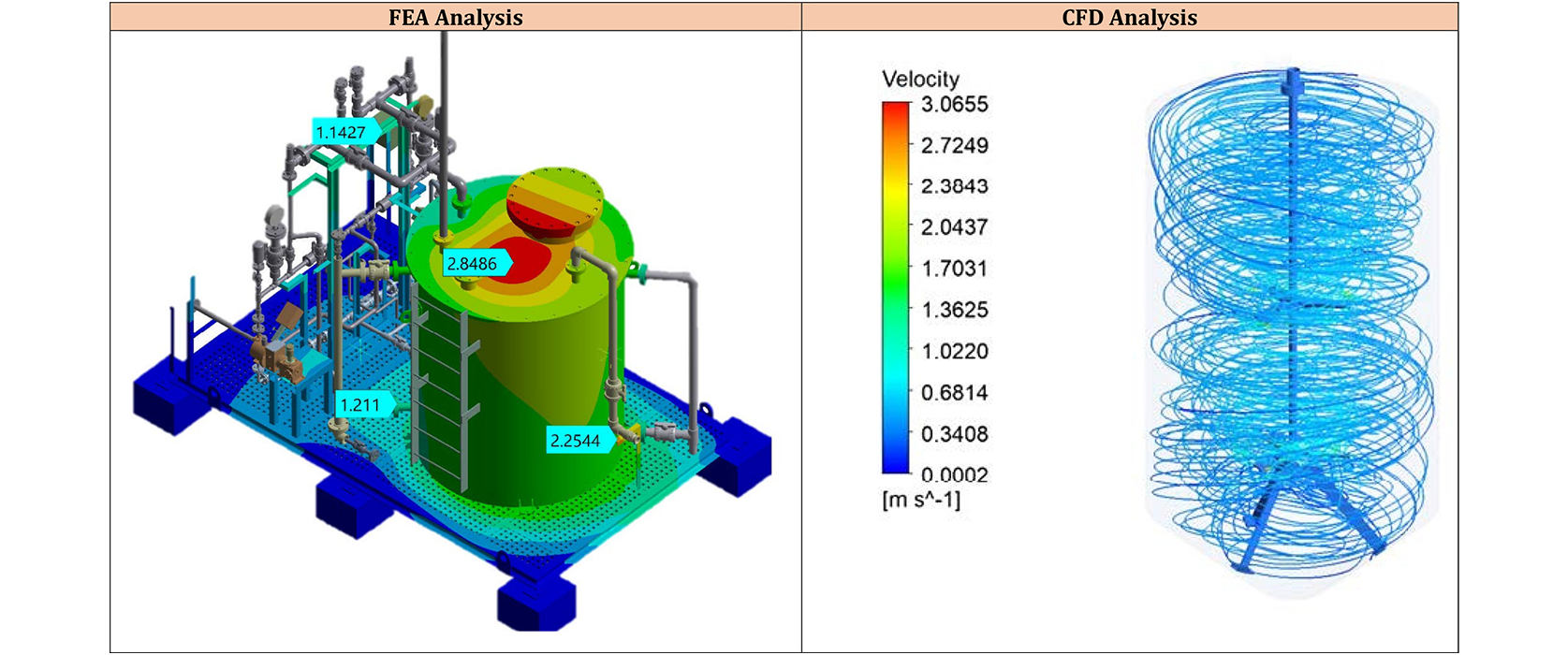

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

| Parameter | Specification |

|---|---|

| System Type | Fully Automatic, Skid Mounted |

| Operation | Batch-wise / Continuous |

| Control System | PLC Based with Touchscreen HMI |

| Transfer Mechanism | Gravity-fed from Preparation to Dosing Tank |

| Mounting Structure | Heavy-Duty MS with Epoxy Coating or SS304 Fabricated Frame |

| Access | Maintenance Platform with Ladder and Handrails (Optional) |

| Parameter | Specification |

|---|---|

| Capacity | 300 L to 5000 L (Customizable) |

| MOC (Tank) | SS304 / SS316 / FRP / HDPE (based on application) |

| MOC (Agitator Shaft & Impeller) | SS304 / SS316 with TEFLON coating (Optional) |

| Agitator Type | Top Entry with Helical or Anchor Paddle or Hydrofoil Blade |

| Motor & Gearbox | TEFC / Flameproof (as per zone), Inline or Helical, IP55/65 rated |

| Powder Dosing System | Hopper with Controlled Screw Feeder & Vibrator |

| Dosing Option | Metering Pump with Calibration Column |

| Water Control | Solenoid/Actuated Ball Valve with Flow Meter |

| Instrumentation | Level Sensor, Low-High Level Switches, Batch Timer, Flow Sensor |

| Safety Features | Dry-Run Protection, Interlock with Agitator |

| Parameter | Specification |

|---|---|

| Capacity | 300 L to 5000 L (Customizable) |

| MOC | SS304 / SS316 / HDPE / FRP |

| Agitation (Optional) | Slow Speed Agitator (if required for anti-settling) |

| Instrumentation | Low Level Switch, Drain Valve, Level Indicator |

| Discharge | Bottom Drain with Flanged/Threaded Connection |

| Parameter | Specification |

|---|---|

| Dosing Pump Type | Solenoid Diaphragm / Motorized Diaphragm / Plunger Pump |

| Flow Range | 0.5 LPH to 5000 LPH (as per client requirement) |

| Discharge Pressure | Up to 10 bar |

| MOC of Wetted Parts | SS316 / PTFE / PVC / PP / Hastelloy (as per fluid compatibility) |

| Accessories | Calibration Column, Pressure Relief Valve, Pulsation Dampener, NRV, Strainer |

| Pump Drive | VFD Controlled for Dosing Adjustments |

| Parameter | Specification |

|---|---|

| Control Panel | SS304 / MS Powder Coated with Internal Wiring |

| PLC Make | Siemens / Schneider / Allen Bradley / Delta (as per client preference) |

| HMI | 7” or 10” Touchscreen – Password Protected |

| Communication | MODBUS / PROFIBUS / Ethernet / SCADA / IoT (Optional) |

| Alarm & Interlock | Buzzer + Indicator + System Shutdown |

| Data Logging | USB/SD Card or Remote Access |

| Parameter | Specification |

|---|---|

| Tanks | SS304 / SS316 / FRP / HDPE |

| Frame | MS Powder Coated / SS304 |

| Agitator Shaft | SS316 / SS304 with Coating |

| Wetted Pump Parts | SS316 / PTFE / PVC / PP |

| Valves & Piping | SS304 / UPVC / CPVC / PP |

| Panel Enclosure | SS304 / CRCA Powder Coated |

Applications

Why Choose Verito Engineering?