Get Your Free Quote…!

Purpose: The primary objective of an ammonia dosing system is to provide a controlled and regulated means of introducing ammonia into a process, ensuring that it aligns with the specific requirements of the water treatment application. This precision helps achieve effective treatment outcomes while maintaining compliance with regulatory standards.

Overview: The dosing system typically consists of one or more chemical storage tanks, pumps to deliver the chemicals to the injection point, and a control system to regulate the amount of chemical injected. The control system may be based on a feedback loop that monitors process parameters such as pH, conductivity, or turbidity, or it may be based on a set time schedule.s

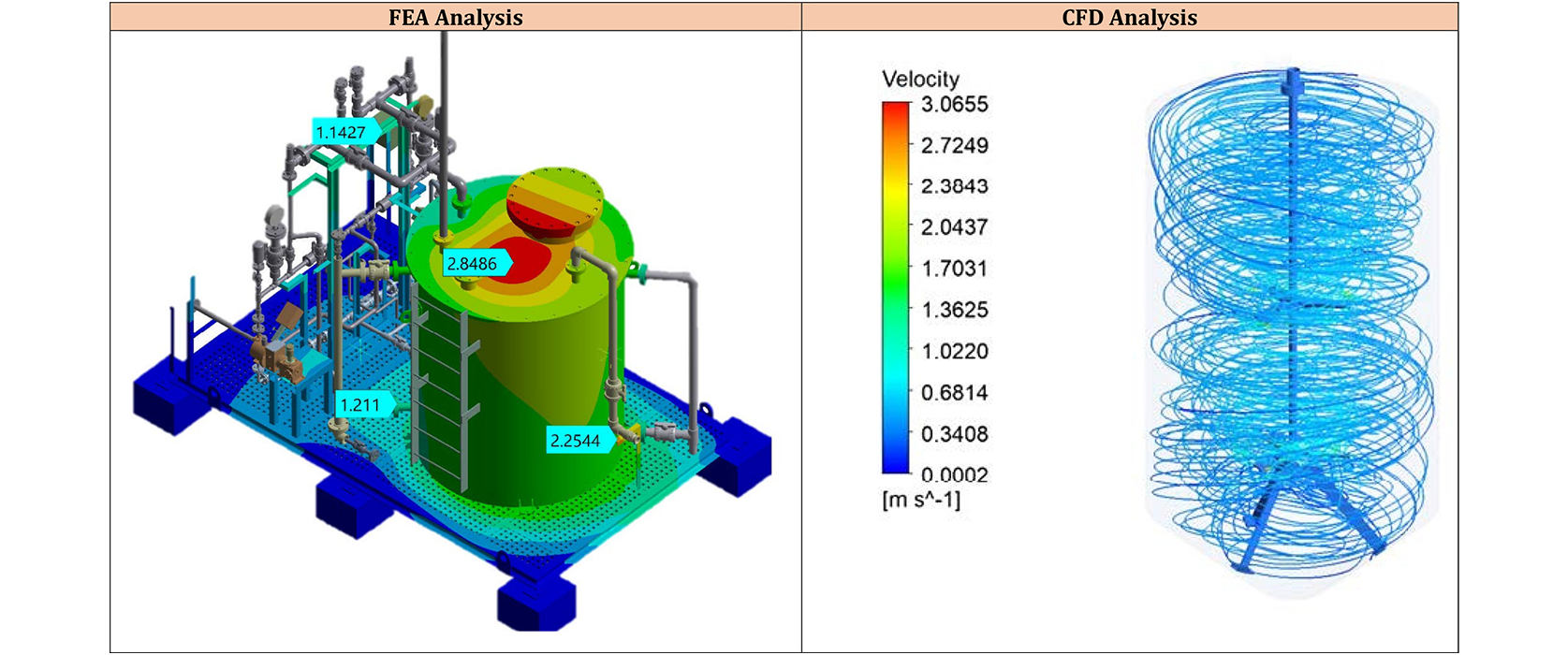

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

Storage Tank: This tank stores the ammonia solution, and its capacity depends on the specific needs of the application. The concentration of the ammonia solution may vary based on the intended use.

Dosing Pump A dosing pump is responsible for accurately injecting or dosing the required amount of ammonia into the water or process stream. This pump ensures a controlled and consistent dosage, contributing to the precision of the ammonia introduction.

Control System: The control system manages the dosing rate based on various parameters such as water quality, pH levels, or other specific requirements. This helps maintain the desired conditions in the water treatment process by adjusting the ammonia dosage as needed.

Ammonia dosing systems are commonly employed in water treatment processes for several purposes:

pH Adjustment: Ammonia is used to increase the pH in water treatment processes where alkalinity is required.

Dechlorination: Ammonia can neutralize chlorine, forming chloramines, which are less harmful and longer-lasting disinfectants.

Nutrient Addition: Ammonia serves as a nutrient in biological treatment processes, supporting the growth of beneficial microorganisms.

Selective Precipitation: Ammonia can be used to selectively precipitate specific ions or metals from water, aiding in their removal.