Get Your Free Quote…!

Overview: The Oxygen Scavenger Injection Package is a critical system designed to remove dissolved oxygen from boiler feedwater, pipelines, and process systems, preventing corrosion, pitting, and scaling in industrial and oil & gas applications. Oxygen scavengers, such as sodium sulfite, hydrazine, or DEHA (Diethylhydroxylamine), are injected in precise amounts to protect metal surfaces and extend the lifespan of equipment.

Verito’s Oxygen Scavenger Injection Package is a custom-engineered, skid-mounted system that ensures efficient and controlled chemical dosing, improving system reliability and performance.

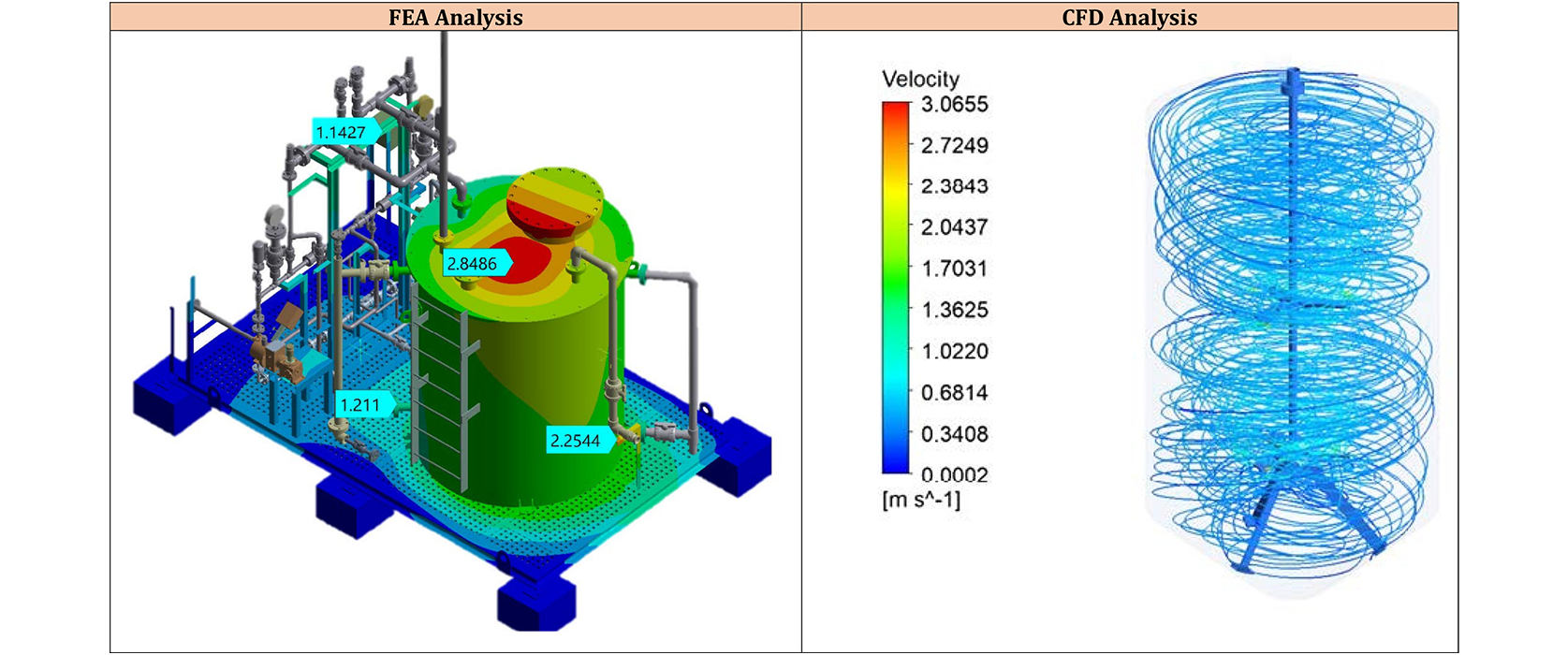

At Verito Engineering Private Limited, we specialize in providing comprehensive engineering analysis and calculations for Skid-Mounted Chemical Injection Packages, ensuring superior performance, reliability, and compliance with global industry standards.

Our expertise covers Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Structural, Mechanical, Hydraulic, and Thermal Calculations for all critical skid components, including:

| Pressure Vessel Calculations | API 675-Compliant Dosing Pump Selection & Sizing | Agitator & Mixing Calculations (For Chemical Preparation Skids) |

|---|---|---|

|

|

|

| Automation & Instrumentation for Optimized Operations | Piping Stress & Pressure Calculations | Structural & Skid Frame Analysis |

|

|

|

| Strainer Calculations | Safety & PSV Sizing Calculations | Injection Quill |

|

|

|

| Material Selection & Corrosion Analysis | Operational Efficiency & Cost Reduction | |

|

|

Applications

Key Features

| Flow Rate | Up to 10,000 LPH (customizable) |

| Discharge Pressure | Up to 500 bar |

| Pump Type | Plunger/Diaphragm/Hydraulic Actuated |

| Material of Construction | SS 316L, Duplex SS, Super Duplex, Alloy 625 |

| Control System | PLC/SCADA with remote monitoring |

| Power Supply | 230V/415V, 50Hz/60Hz |

| Skid Design | Fully integrated, modular, and pre-assembled |