Dosing pumps, essential components in numerous industrial processes, play a crucial role in accurately delivering precise quantities of liquids. From chemical manufacturing to water treatment, these pumps ensure the efficiency, safety, and quality of various operations. This article explores the significance of precision in dosing pumps and how they contribute to the success of various industries.

Dosing pumps are designed to deliver a specific volume of liquid at a controlled rate. They are often used to dispense chemicals, additives, or other substances into a larger process stream. This precise control is essential for maintaining optimal process conditions and preventing errors or inefficiencies.

Importance of Precision In Dosing Pumps

Product Quality

- Consistency: Accurate dosing ensures that products meet consistent quality standards. In industries like pharmaceuticals and food processing, deviations can lead to product defects or safety hazards.

- Performance: The precise delivery of additives or chemicals can optimize product performance. For example, in the textile industry, the correct dosage of dyes ensures vibrant colors and even dyeing.

Process Efficiency

- Cost Reduction: Precise dosing helps minimize waste by preventing overdosing or underdosing. This can lead to significant cost savings, especially when dealing with expensive materials.

- Optimized Processes: Accurate dosing allows for the efficient operation of industrial processes. For instance, in water treatment, the correct dosage of chemicals ensures effective purification and prevents unnecessary treatment steps.

Safety

- Hazard Prevention: In industries involving hazardous chemicals, precise dosing is crucial to prevent accidents. Overdosing can lead to dangerous reactions, while underdosing may not achieve the desired effect.

- Worker Safety: Accurate dosing helps protect workers from exposure to harmful substances. By ensuring that chemicals are delivered in the correct quantities, the risk of accidents and health hazards is minimized.

Environmental Compliance

- Pollution Reduction: Precise dosing can help minimize the discharge of pollutants into the environment. By avoiding overdosing, industries can reduce their environmental footprint and comply with regulations.

- Sustainable Practices: Accurate dosing contributes to sustainable practices by optimizing resource usage and minimizing waste.

Applications of Dosing Pumps

Dosing pumps are used in a wide range of industries, including:

- Chemical Manufacturing: Used to dispense catalysts, solvents, and other chemicals in various manufacturing processes.

- Water Treatment: Used to add coagulants, disinfectants, and other chemicals to treat water for drinking, industrial, and wastewater applications.

- Food and Beverage Processing: Used to add flavors, preservatives, and other ingredients to food and beverages.

- Pharmaceutical Manufacturing: Used to dispense active ingredients and excipients in the production of pharmaceuticals.

- Pulp and Paper Industry: Used to add chemicals for process control and quality assurance.

- Textile Industry: Used to add dyes and chemicals during the dyeing and finishing processes.

Factors Affecting Precision

Several factors can influence the precision of dosing pumps, including:

- Pump Type: Different pump types have varying levels of precision. Positive displacement pumps, such as diaphragm and plunger pumps, are generally more accurate than centrifugal pumps.

- Pump Design: The design of the pump, including the materials used and the precision of the components, can affect accuracy.

- Maintenance and Calibration: Regular maintenance and calibration are essential to ensure the pump continues to operate accurately.

- Process Conditions: Factors such as pressure, temperature, and viscosity can affect the pump’s performance and precision.

Precision in dosing pumps is essential for ensuring the success of numerous industrial processes. By accurately delivering the required quantities of liquids, dosing pumps contribute to product quality, process efficiency, safety, and environmental compliance. As industries continue to evolve and become more demanding, the importance of precise dosing will only increase.

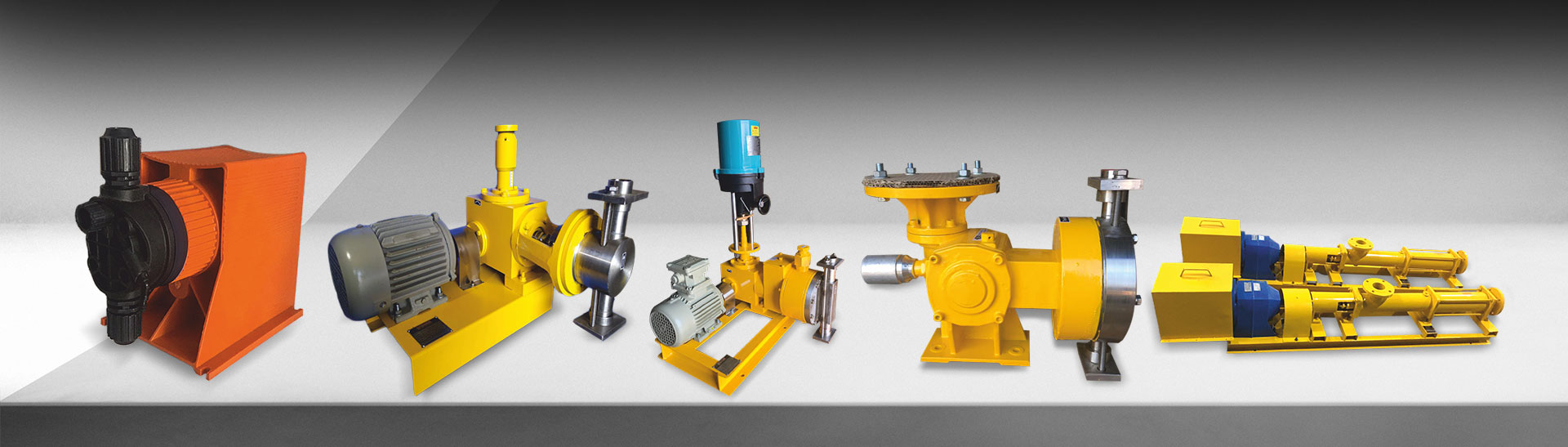

Verito Engineering Pvt Ltd, a renowned manufacturer of dosing pumps, has established itself as a leader in providing high-quality and precise solutions for various industrial applications. With a commitment to innovation and excellence, Verito Engineering Pvt Ltd offers a wide range of dosing pumps tailored to meet the specific needs of different industries. Their pumps are known for their reliability, durability, and accuracy, making them an essential component in ensuring optimal process performance and product quality. Verito Engineering Pvt Ltd’s dedication to customer satisfaction and continuous improvement has solidified their position as a trusted partner in the field of dosing pump technology.