Dosing pumps are crucial in industries where precise chemical delivery is necessary, such as water treatment, manufacturing, and food processing. Proper installation of a dosing pump ensures optimal performance, accuracy, and longevity.

To know more about dosing pumps, check out our blog titled – What is a Dosing Pump? Types, Applications, and Buying Tips

How to Install Doing Pump

-

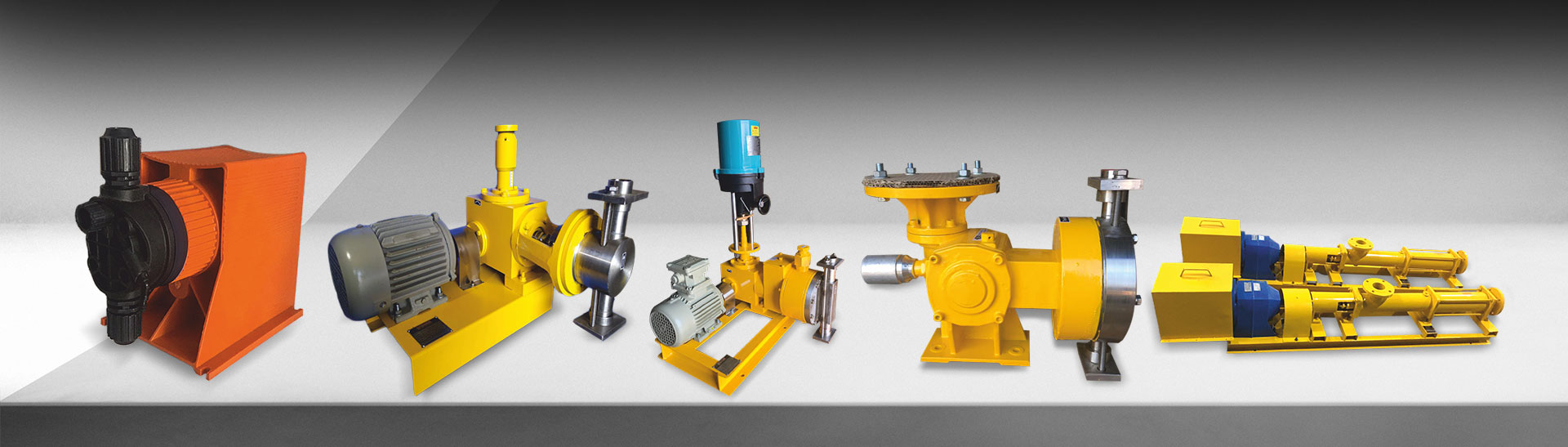

Understanding the Dosing Pump Components

Before beginning the installation, familiarize yourself with the main components of a dosing pump:

- Pump Head: The section that houses the diaphragm, valves, and connectors.

- Motor: Powers the pump.

- Control Unit: Adjusts the flow rate and other settings.

- Suction and Discharge Lines: Connect to the chemical storage and injection point.

-

Selecting the Installation Site

- Location: Choose a stable, well-ventilated area, protected from extreme weather conditions.

- Proximity: Position the pump as close to the dosing point as possible to reduce the length of suction and discharge lines.

- Accessibility: Ensure that the pump is easy to access for maintenance and inspection.

-

Mounting the Pump

- Surface Preparation: Make sure the mounting surface is level and strong enough to support the pump.

- Mounting Bracket: Use the appropriate mounting bracket (usually provided with the pump) to secure the pump to the wall or surface.

- Alignment: Ensure that the pump is aligned vertically to avoid strain on the internal components.

-

Connecting the Suction Line

- Check Valve Installation: Install a check valve at the end of the suction line to prevent backflow and maintain prime.

- Suction Line Connection: Attach the suction line to the pump inlet securely, ensuring that there are no leaks.

- Priming: Fill the suction line with the chemical to be dosed, ensuring the line is free from air bubbles.

-

Connecting the Discharge Line

- Pressure Relief Valve: Install a pressure relief valve on the discharge line to protect the pump and system from overpressure.

- Discharge Line Connection: Connect the discharge line to the pump outlet. Ensure that the line is properly secured and free of kinks.

- Check for Leaks: Tighten all connections and check for any leaks in the discharge line.

-

Electrical Connections

- Power Supply: Ensure that the pump is connected to a power supply that matches its voltage and frequency requirements.

- Grounding: Properly ground the pump to prevent electrical hazards.

- Control Wiring: If the pump is controlled by an external device (e.g., a PLC), connect the control wires according to the manufacturer’s instructions.

-

Calibrating the Pump

- Flow Rate Adjustment: Set the desired flow rate using the control unit. The flow rate is usually adjustable through the pump’s stroke length and speed.

- Calibration Test: Run the pump and measure the output to verify the flow rate. Adjust as necessary to achieve the desired dosing rate.

- Verify Operation: Once calibrated, run the pump for a short period to ensure that it operates smoothly without any issues.

-

Final Inspection and Testing

- System Pressure Test: Pressurize the system and check for any leaks or pressure drops.

- Operation Check: Run the pump under normal operating conditions and observe its performance.

- Safety Features: Test any safety features, such as alarms or shut-offs, to ensure they are functioning correctly.

-

Maintenance Considerations

- Routine Checks: Regularly inspect the pump for wear, leaks, and proper operation.

- Component Replacement: Replace worn components, such as diaphragms and valves, according to the manufacturer’s maintenance schedule.

- Documentation: Keep a log of maintenance activities and any adjustments made to the pump settings.

Proper installation of a dosing pump is critical to ensure its longevity and reliable operation. By following the steps outlined in our “How to install dosing pump” guide, you can install your dosing pump with confidence, knowing that it will function effectively in your application. Regular maintenance and inspections will further ensure that the pump continues to operate efficiently and safely.

At Verito Engineering Pvt Ltd, we take pride in being one of the leading manufacturers of high-quality dosing pumps. Check out this link to explore more about dosing pump installation. Our team is dedicated to providing you with the best products and support for all your dosing needs.