Dosing pumps play an essential role in modern food and beverage manufacturing, where precision and consistency are paramount. From flavorings to preservatives, many ingredients must be added in exact amounts to maintain product quality, safety, and compliance with strict industry regulations. Dosing pumps provide the accuracy needed for precise ingredient control, which is vital for high-quality food and beverage production.

Importance of Dosing Pumps in the Food and Beverage Industry

In food and beverage production, maintaining uniform taste, color, and quality is critical. Dosing pumps allow manufacturers to control ingredient proportions down to micro-levels, ensuring the desired consistency for each batch. By precisely metering fluids, dosing pumps reduce waste and optimize efficiency. With the benefits of reduced material costs and enhanced product quality, dosing pumps are integral to any production process requiring accurate ingredient measurement.

Applications of Dosing Pumps in Food and Beverage Production

Flavoring and Coloring Additives

Dosing pumps are used to add flavors and colors in controlled amounts, critical for products such as soft drinks, dairy, and confectionery. This ensures the product’s taste and appearance remain uniform across batches.

Preservatives and Acidity Control

To extend shelf life and maintain stability, preservatives and acidity regulators are commonly added. Dosing pumps enable precise dispensing, meeting regulatory standards and preventing spoilage.

Nutrient and Vitamin Fortification

For health-oriented foods and beverages, manufacturers often add vitamins, minerals, or other nutrients. Dosing pumps are ideal for these applications, as they ensure the correct levels of fortification without affecting flavor.

Carbonation and Syrup Dispensing

Carbonated beverages require the accurate addition of syrup and carbonation. Dosing pumps ensure each drink has the right sweetness and fizz, essential for consumer satisfaction and brand consistency.

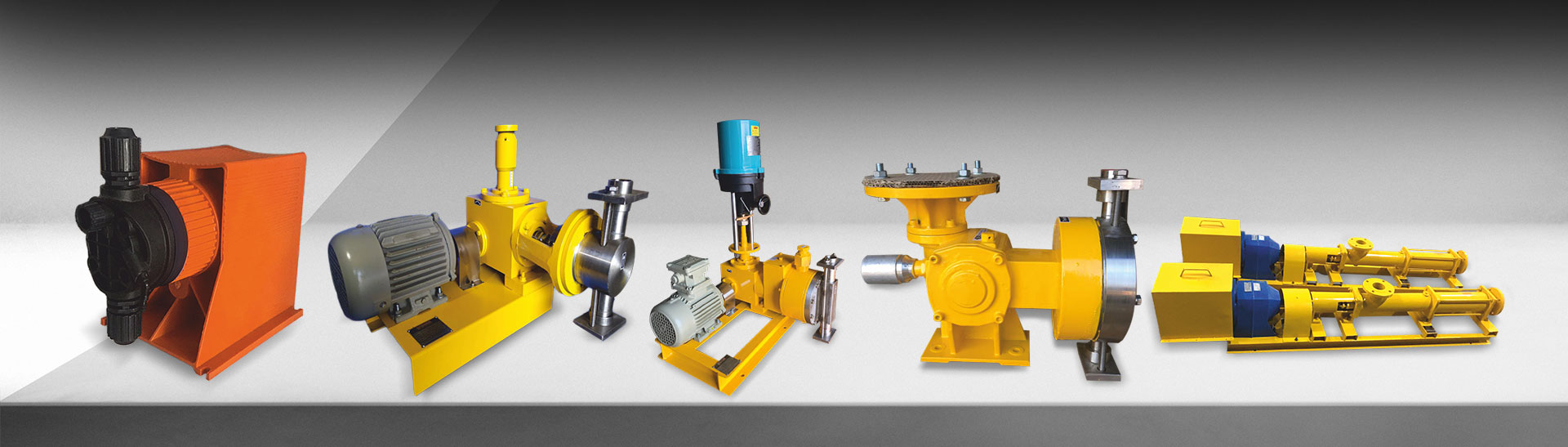

Types of Dosing Pumps Commonly Used in the Food and Beverage Industry

-

Peristaltic Pumps

Known for their gentle pumping action, peristaltic pumps are often used for food-grade applications that require sanitary conditions. These pumps prevent contamination and are ideal for dispensing viscous and shear-sensitive fluids.

-

Diaphragm Pumps

Diaphragm dosing pumps are valued for their high precision and durability, making them suitable for handling abrasive or viscous additives in food processing.

-

Piston Pumps

These pumps are preferred for high-pressure applications and can handle viscous materials like syrups and other concentrated ingredients.

Each pump type offers specific benefits and suits particular applications within the food and beverage industry, based on requirements like pressure, flow rate, and fluid characteristics.

Compliance and Sanitary Standards

Food and beverage production requires strict adherence to regulatory standards to ensure consumer safety. Dosing pumps used in this industry must meet food-grade standards set by authorities such as the FDA and adhere to hygiene practices, including CIP (Clean-in-Place) and SIP (Sterilize-in-Place) capabilities. These features help prevent cross-contamination, ensuring that the pumps can be easily cleaned and sterilized between batches.

Advantages of Using Dosing Pumps in Food and Beverage Production

-

Enhanced Product Quality

Consistent ingredient ratios mean the end product’s taste, appearance, and nutritional value remain uniform, ensuring a reliable consumer experience.

-

Cost Efficiency

Dosing pumps reduce ingredient waste by delivering precise amounts, minimizing losses of costly ingredients like flavors, colorants, and vitamins.

-

Operational Efficiency

Automation in dosing systems reduces the need for manual measurements, minimizing the potential for human error. This enhances productivity, particularly in high-volume production lines.

-

Environmental Benefits

By optimizing ingredient use, dosing pumps contribute to sustainability goals by reducing waste. They also help cut down on overuse of ingredients, lowering a facility’s environmental impact.

Key Considerations When Selecting a Dosing Pump for Food Applications

Selecting the right dosing pump involves assessing factors like flow rate, material compatibility, hygiene standards, and the specific type of food-grade certification required. Pumps must also handle varying viscosities, operate under appropriate temperature ranges, and be resistant to potential contamination sources. Ensuring that the pump design meets both production needs and regulatory standards is essential for seamless and compliant food manufacturing.

Dosing pumps are indispensable tools in food and beverage production, offering precision and control that are vital for high-quality manufacturing. With the ability to handle a range of fluids, from flavorings to preservatives, dosing pumps help manufacturers meet stringent regulatory requirements and improve operational efficiency. Choosing the right dosing pump enables food and beverage companies to maintain quality, reduce waste, and uphold their commitment to safety and sustainability.

Verito Engineering Pvt Ltd stands as a trusted manufacturer of high-quality dosing pumps, offering reliable solutions tailored to meet the unique demands of food and beverage production.